How to Choose the Right Copper wire drawing machine for Your Business

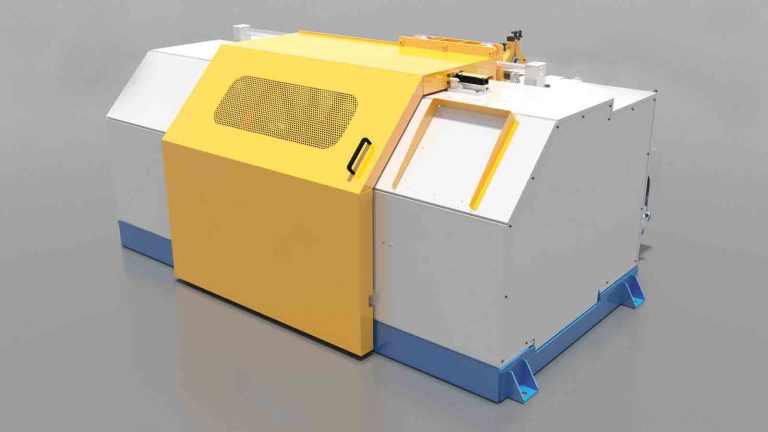

Copper wire drawing machines are essential equipment for businesses involved in the production of copper wires. These machines are used to reduce the diameter of copper rods or wires by pulling them through a series of dies, resulting in a smoother and more uniform wire. Choosing the right copper wire drawing machine for your business is crucial to ensure efficient production and high-quality output.

When selecting a copper wire drawing machine, there are several factors to consider. The first consideration is the size and type of copper wire you will be producing. Different machines are designed to handle different wire sizes and types, so it is important to choose a machine that is suitable for your specific requirements. Additionally, consider the production capacity of the machine. If you have a high volume of wire production, you will need a machine that can handle the workload efficiently.

Another important factor to consider is the number of dies on the machine. The number of dies determines the number of times the wire will be drawn through the machine, which affects the final diameter of the wire. Machines with more dies are capable of producing finer wires, while machines with fewer dies are better suited for thicker wires. Consider your desired wire diameter and choose a machine with the appropriate number of dies to achieve the desired results.

It is also important to consider the speed of the machine. The speed at which the wire is drawn through the machine affects the production efficiency and output quality. Machines with variable speed control allow you to adjust the drawing speed according to your production needs. Additionally, consider the power consumption of the machine. Choose a machine that is energy-efficient to reduce operating costs and environmental impact.

When choosing a copper wire drawing machine, it is important to consider the quality and reputation of the manufacturer. Look for a reputable manufacturer with a track record of producing high-quality machines. Read customer reviews and testimonials to gauge the reliability and performance of the machine. Additionally, consider the warranty and after-sales support provided by the manufacturer. A reliable manufacturer will offer a warranty and provide technical support to ensure the smooth operation of the machine.

In conclusion, choosing the right copper wire drawing machine for your business is essential to ensure efficient production and high-quality output. Consider factors such as wire size, production capacity, number of dies, speed, power consumption, and manufacturer reputation when selecting a machine. By carefully evaluating these factors, you can choose a machine that meets your specific requirements and helps you achieve success in the production of copper wires. Invest in a high-quality copper wire drawing machine to enhance your production capabilities and stay ahead of the competition.

Benefits of Using Copper Wire Drawing Machines in Industrial Applications

Copper wire drawing machines play a crucial role in industrial applications where the production of copper wire is required. These machines are designed to pull a copper rod through a series of dies to reduce its diameter and increase its length. This process is known as wire drawing and is essential for creating copper wire of various sizes and gauges.

One of the key benefits of using Staple Wire Wet Drawing Machine is the ability to produce copper wire with precise dimensions. By controlling the speed at which the copper rod is pulled through the dies, manufacturers can create wire of specific diameters to meet the requirements of their customers. This level of precision is essential in industries such as electronics, telecommunications, and construction, where copper wire is used in a wide range of applications.

In addition to producing wire with precise dimensions, copper wire drawing machines also offer the advantage of improving the mechanical properties of the copper wire. As the wire is drawn through the dies, its grain structure is refined, resulting in increased strength and ductility. This makes the wire more durable and resistant to breakage, which is important in applications where the wire is subjected to high levels of stress or strain.

Another benefit of using copper wire drawing machines is the ability to produce wire with a smooth surface finish. The dies used in the drawing process are designed to remove any surface imperfections or defects, resulting in wire that is free from burrs or rough spots. This smooth surface finish not only improves the appearance of the wire but also reduces friction and wear when the wire is used in machinery or equipment.

Copper wire drawing machines also offer the advantage of increasing the length of the copper wire. By pulling the copper rod through a series of dies, manufacturers can create wire that is significantly longer than the original rod. This allows for more efficient production processes and reduces the need for frequent spool changes or interruptions in production.

Furthermore, copper wire drawing machines are highly efficient and cost-effective. These machines are designed to operate at high speeds, allowing manufacturers to produce large quantities of copper wire in a relatively short amount of time. This increased productivity results in lower production costs and higher profit margins for manufacturers.

Overall, the benefits of using copper wire drawing machines in industrial applications are clear. From producing wire with precise dimensions and improved mechanical properties to creating wire with a smooth surface finish and increased length, these machines offer a wide range of advantages for manufacturers. With their efficiency and cost-effectiveness, copper wire drawing machines are an essential tool for any industry that requires the production of copper wire.