Merits of Using a Continuous wire drawing machine

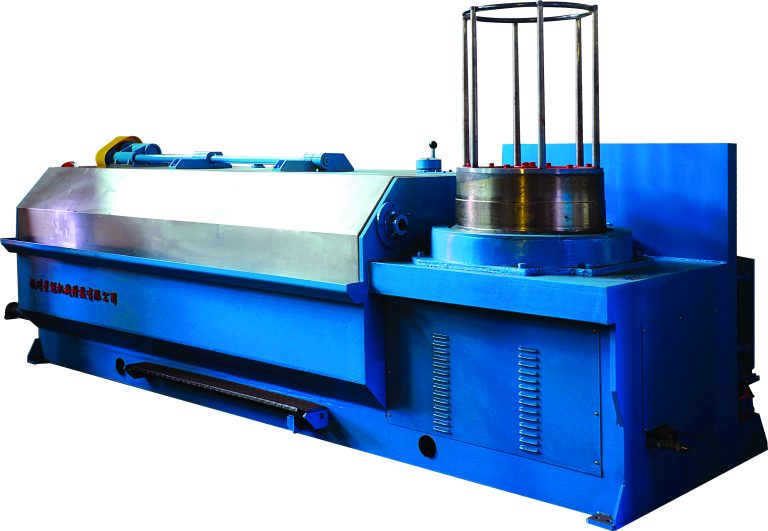

A continuous wire drawing machine is a crucial piece of equipment in the manufacturing industry, particularly in the production of wires and cables. This machine is designed to pull a wire through a series of dies to reduce its diameter and increase its length. The process is continuous, meaning that the wire is drawn through multiple dies in one seamless operation. There are several benefits to using a continuous wire drawing machine, which we will explore in this article.

One of the primary advantages of a Straight line wire drawing machine is its efficiency. By continuously pulling the wire through a series of dies, the machine can produce long lengths of wire in a short amount of time. This can significantly increase productivity and reduce production costs. Additionally, the machine can be set up to run automatically, allowing for continuous operation without the need for constant supervision.

Another benefit of using a continuous wire drawing machine is the ability to produce wires with precise dimensions. The dies in the machine can be adjusted to control the diameter of the wire, ensuring that the final product meets the required specifications. This level of precision is essential in industries where the quality of the wire is critical, such as in the production of electrical cables or medical devices.

In addition to producing wires with precise dimensions, Fine Wire Drawing Machine with continuous annealing can also improve the surface finish of the wire. As the wire is pulled through the dies, any imperfections or irregularities on the surface are smoothed out, resulting in a clean and uniform finish. This is important in applications where the appearance of the wire is important, such as in jewelry making or automotive manufacturing.

Furthermore, using a continuous wire drawing machine can help reduce material waste. The machine is designed to pull the wire through the dies at a consistent rate, minimizing the amount of material that is wasted during the drawing process. This can lead to cost savings for manufacturers and a more sustainable production process.

Additionally, a continuous wire drawing machine can improve the mechanical properties of the wire. As the wire is drawn through the dies, it undergoes a process of work hardening, which can increase its strength and durability. This is important in applications where the wire will be subjected to high levels of stress or wear, such as in the construction industry or in the production of industrial machinery.

In conclusion, the benefits of using a continuous wire drawing machine are numerous. From increased efficiency and productivity to improved precision and surface finish, this machine offers a range of advantages for manufacturers in various industries. By investing in a continuous wire drawing machine, manufacturers can enhance their production processes, reduce costs, and improve the quality of their products.