How to Properly Maintain and Extend the Lifespan of Aluminum Alloy Wire

Aluminum alloy wire machine is a popular choice for various applications due to its lightweight and corrosion-resistant properties. However, like any other material, aluminum alloy wire requires proper maintenance to ensure its longevity and performance. In this article, we will discuss some tips on how to properly maintain and extend the lifespan of aluminum alloy wire.

One of the most important aspects of maintaining aluminum alloy wire is to keep it clean. Dirt, dust, and other contaminants can accumulate on the surface of the wire, leading to corrosion and reduced conductivity. To clean aluminum alloy wire, simply wipe it down with a clean, damp cloth. Avoid using harsh chemicals or abrasive materials, as these can damage the wire’s surface.

In addition to keeping the wire clean, it is also important to inspect it regularly for any signs of damage or wear. Look for any kinks, bends, or breaks in the wire, as these can weaken its structural integrity and lead to failure. If you notice any damage, it is important to address it promptly to prevent further issues.

Another important aspect of maintaining aluminum alloy wire is to protect it from environmental factors that can accelerate corrosion. Exposure to moisture, salt, and other corrosive substances can cause the wire to deteriorate quickly. To protect aluminum alloy wire from corrosion, consider applying a protective coating or using a corrosion-resistant sealant.

Proper storage is also crucial for maintaining aluminum alloy wire. Store the wire in a dry, cool place away from direct sunlight and extreme temperatures. Avoid storing the wire in areas where it can come into contact with moisture or corrosive substances. Additionally, make sure to coil the wire properly to prevent kinks and bends that can weaken its structure.

Regularly inspecting and testing aluminum alloy wire is essential for ensuring its performance and longevity. Use a multimeter to check the conductivity of the wire and look for any signs of deterioration. If you notice any issues, it is important to address them promptly to prevent further damage.

In conclusion, proper maintenance is key to extending the lifespan of aluminum alloy wire. By keeping the wire clean, inspecting it regularly, protecting it from environmental factors, storing it properly, and testing it regularly, you can ensure that your aluminum alloy wire performs optimally for years to come. Remember to address any issues promptly to prevent further damage and ensure the longevity of your aluminum alloy wire.

Benefits of Using Aluminum Alloy Wire in Electrical Applications

Aluminum alloy wire is a popular choice for electrical applications due to its numerous benefits. One of the main advantages of using aluminum alloy wire is its lightweight nature. Compared to copper wire, aluminum alloy wire is significantly lighter, making it easier to handle and install. This can be especially beneficial in large-scale electrical projects where a significant amount of wire is needed.

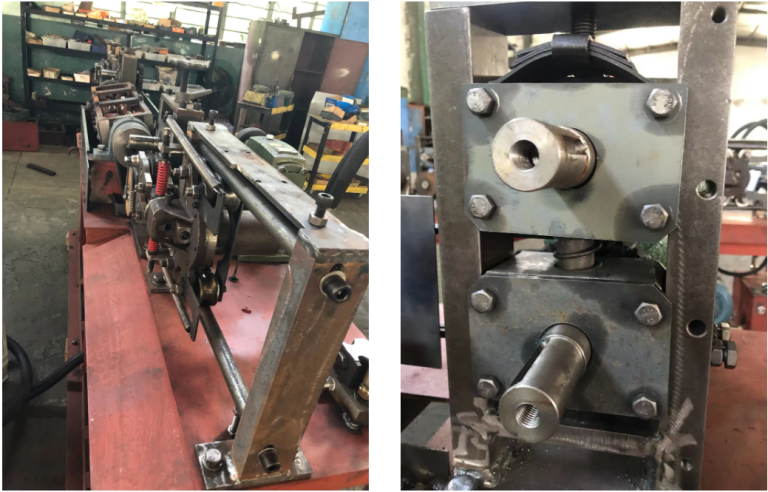

In addition to its lightweight nature, Aluminum wire breakdown drawing machine for cable aluminum wire is also highly conductive. This means that it can efficiently carry electrical currents without experiencing significant voltage drops. This is crucial in electrical applications where consistent and reliable power transmission is essential. The high conductivity of aluminum alloy wire also allows for efficient energy transfer, which can help reduce energy costs in the long run.

Another key benefit of using aluminum alloy wire is its cost-effectiveness. Aluminum is a more abundant and less expensive material compared to copper, making aluminum alloy wire a more budget-friendly option for electrical projects. This cost savings can be particularly advantageous for large-scale projects where the cost of materials can quickly add up.

Furthermore, aluminum alloy wire is highly resistant to corrosion, making it a durable option for outdoor and underground electrical applications. This resistance to corrosion helps prolong the lifespan of the wire, reducing the need for frequent replacements and maintenance. Additionally, aluminum alloy wire is also resistant to thermal expansion, which can help prevent damage to the wire in extreme temperature conditions.

In terms of sustainability, aluminum alloy wire is a more environmentally friendly option compared to copper wire. Aluminum is a highly recyclable material, and using aluminum alloy wire can help reduce the demand for new raw materials. This can contribute to a more sustainable and eco-friendly approach to electrical projects.

Despite its numerous benefits, there are some considerations to keep in mind when using aluminum alloy wire. One potential drawback is that aluminum alloy wire has a lower tensile strength compared to copper wire, which can make it more susceptible to damage during installation. It is important to handle aluminum alloy wire with care to prevent any bending or kinking that could compromise its performance.

Additionally, aluminum alloy wire has a higher coefficient of thermal expansion compared to copper wire, which can lead to issues with connections and terminations if not properly accounted for. It is important to follow manufacturer guidelines and best practices when working with aluminum alloy wire to ensure proper installation and performance.

In conclusion, aluminum alloy wire offers a range of benefits for electrical applications, including its lightweight nature, high conductivity, cost-effectiveness, durability, and sustainability. While there are some considerations to keep in mind, such as lower tensile strength and thermal expansion, the advantages of using aluminum alloy wire make it a popular choice for a variety of electrical projects. By understanding the benefits and potential challenges of aluminum alloy wire, electrical professionals can make informed decisions when selecting materials for their projects.