Maintenance Tips for Full Automatic Nail Making Machines

Nail making machines are essential tools for businesses in the construction, manufacturing, and woodworking industries. These machines automate the process of creating nails, saving time and labor costs. However, with so many options available on the market, choosing the right Steel Wire Nail Making Machine for your business can be a daunting task. In this article, we will discuss the factors to consider when selecting a nail making machine to ensure that you make the best choice for your business needs.

One of the first things to consider when choosing a wire nail making machine is the production capacity. Different machines have different production capacities, ranging from a few hundred nails per minute to thousands of nails per minute. It is important to assess your business’s production needs and choose a machine that can meet those requirements. Investing in a machine with a higher production capacity than you currently need can help future-proof your business and accommodate growth.

Another important factor to consider is the size and type of nails that the machine can produce. Automatic nail making machines come in various sizes and can produce different types of nails, such as common nails, roofing nails, and finishing nails. It is essential to choose a machine that can produce the type and size of nails that are commonly used in your industry. Additionally, some machines are capable of producing nails with special features, such as twisted shanks or coated finishes. Consider whether these features are necessary for your business before making a decision.

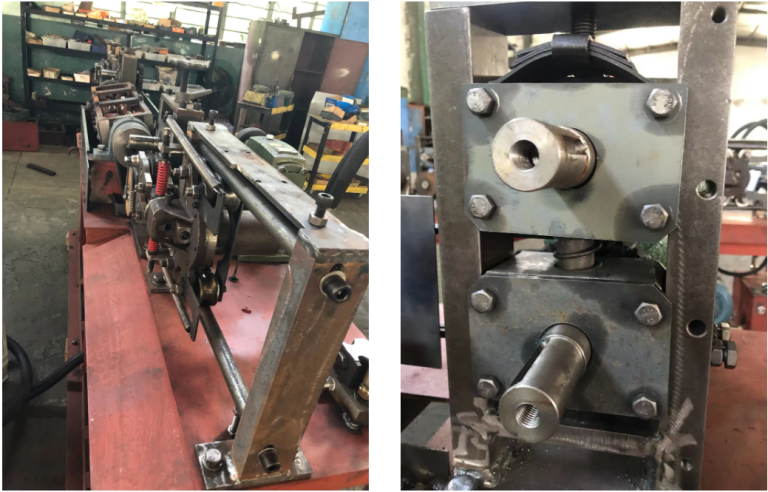

The quality of the nails produced by the machine is another crucial factor to consider. Look for machines that are made from high-quality materials and have a reputation for producing durable and consistent nails. It is also important to consider the maintenance requirements of the machine and whether spare parts are readily available. Investing in a machine that is built to last and easy to maintain can save you time and money in the long run.

Cost is also an important consideration when choosing a wire nail making machine. Prices can vary significantly depending on the machine’s production capacity, features, and quality. It is essential to weigh the upfront cost of the machine against the potential savings in labor costs and increased productivity. Consider your budget and choose a machine that offers the best value for your business.

When selecting a nail making machine, it is also important to consider the manufacturer’s reputation and customer support. Look for manufacturers with a track record of producing high-quality machines and providing excellent customer service. A reputable manufacturer will offer warranties, technical support, and training to help you get the most out of your machine.

In conclusion, choosing the right nail making machine for your business requires careful consideration of factors such as production capacity, nail size and type, quality, cost, and manufacturer reputation. By taking the time to research and evaluate your options, you can ensure that you make the best choice for your business needs. Investing in a high-quality nail making machine can help improve efficiency, reduce costs, and increase productivity in your business.