Benefits of Using an Aluminum wire drawing machine

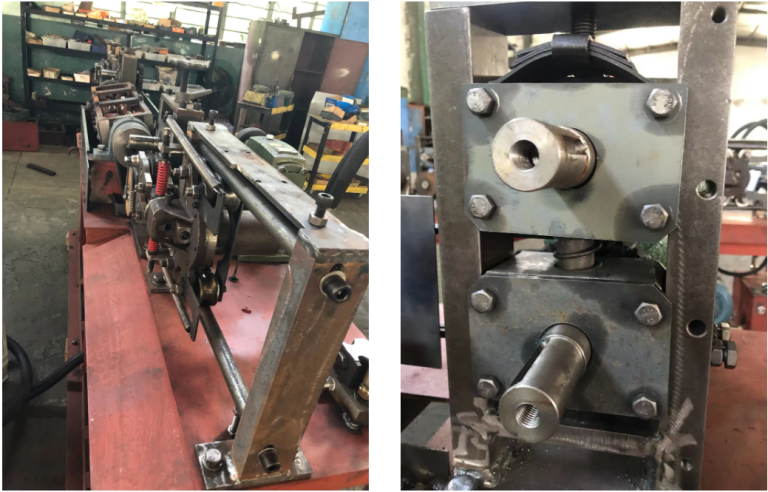

Aluminum wire drawing machines are essential tools in the manufacturing industry for producing high-quality aluminum wires. These machines are designed to pull aluminum rods through a series of dies to reduce their diameter and improve their mechanical properties. The process involves applying pressure and lubrication to the aluminum rod to achieve the desired wire diameter.

One of the key benefits of using an Aluminum wire breakdown drawing machine for cable aluminum wire is the ability to produce wires with precise dimensions. The machine can control the diameter of the wire by adjusting the size of the dies, ensuring consistency in the final product. This is crucial for industries that require uniform wire sizes for their applications, such as electrical wiring, automotive components, and construction materials.

Another advantage of using an Aluminum Alloy Wire machine is the improvement in the mechanical properties of the wire. The drawing process aligns the aluminum grains along the length of the wire, resulting in increased strength and ductility. This makes the wire more suitable for applications that require high tensile strength and flexibility, such as overhead power lines and cables.

In addition to enhancing the mechanical properties of the wire, the drawing process also improves the surface finish of the aluminum wire. The wire is pulled through a series of dies that smooth out any imperfections on the surface, creating a polished and uniform appearance. This is important for applications where the wire will be visible or in contact with other materials, as a smooth surface reduces friction and improves conductivity.

Furthermore, using an aluminum wire drawing machine can increase the production efficiency of a manufacturing facility. The machine can process aluminum rods at high speeds, allowing for rapid production of wires in large quantities. This is beneficial for industries that have high demand for aluminum wires and need to meet tight deadlines.

Moreover, aluminum wire drawing machines are versatile tools that can accommodate a wide range of wire diameters. By changing the size of the dies, manufacturers can produce wires of different thicknesses to meet the requirements of various applications. This flexibility allows for greater customization and adaptability in production processes.

Additionally, aluminum wire drawing machines are cost-effective investments for manufacturing companies. The machines are durable and require minimal maintenance, reducing downtime and repair costs. They also have low energy consumption compared to other wire production methods, making them environmentally friendly and economical to operate.

In conclusion, the benefits of using an aluminum wire drawing machine are numerous and significant for manufacturing industries. From producing wires with precise dimensions and improved mechanical properties to enhancing production efficiency and cost-effectiveness, these machines play a crucial role in the production of high-quality aluminum wires. With their versatility and durability, aluminum wire drawing machines are essential tools for meeting the demands of modern manufacturing processes.