How to Choose the Right Wire pointing machine for Your Needs

Wire pointing and stringing machines are essential tools in the wire manufacturing industry. They are used to remove burrs and sharp edges from wire rods, making them smooth and ready for further processing. Choosing the right wire pointing machine for your needs is crucial to ensure efficient and high-quality wire production. In this article, we will discuss the factors to consider when selecting a wire pointing machine.

One of the first things to consider when choosing a pointing machine is the type of wire you will be processing. Different machines are designed to handle different types and sizes of wire. Some machines are specifically designed for thin wires, while others are better suited for thicker wires. It is important to choose a machine that is compatible with the wire sizes you will be working with to ensure optimal performance.

Another important factor to consider is the production capacity of the wire pointing machine. The production capacity of a machine is determined by its speed and efficiency in removing burrs from wire rods. If you have a high volume of wire production, you will need a machine that can handle large quantities of wire quickly and efficiently. On the other hand, if you have a smaller production volume, a machine with lower production capacity may be sufficient for your needs.

The quality of the wire pointing machine is also an important consideration. A high-quality machine will be more durable and reliable, resulting in less downtime and maintenance costs. Look for machines made from high-quality materials and with a solid construction to ensure long-term performance.

Ease of use is another factor to consider when choosing a wire pointing machine. A machine that is easy to operate and maintain will save you time and effort in the long run. Look for machines with user-friendly controls and features that make operation simple and intuitive. Additionally, consider the maintenance requirements of the machine and choose one that is easy to clean and service.

Cost is also an important consideration when selecting a wire pointing machine. While it is important to invest in a high-quality machine, it is also important to consider your budget constraints. Compare the prices of different machines and consider the long-term costs of maintenance and operation before making a decision.

When choosing a wire pointing machine, it is also important to consider the reputation of the manufacturer. Look for a reputable manufacturer with a track record of producing high-quality machines. Reading reviews and testimonials from other customers can help you gauge the reliability and performance of a particular machine.

In conclusion, choosing the right wire pointing machine for your needs is essential to ensure efficient and high-quality wire production. Consider factors such as the type of wire you will be processing, production capacity, quality, ease of use, cost, and manufacturer reputation when making your decision. By carefully evaluating these factors, you can select a wire pointing machine that meets your requirements and helps you achieve optimal results in your wire manufacturing process.

Maintenance Tips for Keeping Your Wire Pointing Machine in Top Condition

Wire pointing machines are essential tools in the wire manufacturing industry, used to straighten and point wires for various applications. To ensure the efficient operation of your wire pointing machine, regular maintenance is crucial. By following these maintenance tips, you can keep your machine in top condition and prolong its lifespan.

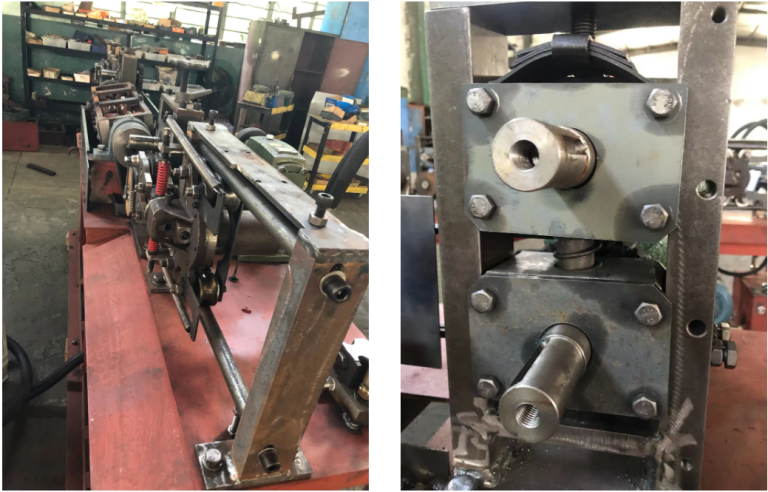

One of the most important maintenance tasks for a wire pointing machine is keeping it clean. Dust, dirt, and debris can accumulate on the machine’s components, leading to decreased performance and potential damage. Regularly clean the machine with a soft brush or cloth to remove any buildup. Pay special attention to the wire guides, rollers, and pointing dies, as these are the areas most prone to dirt accumulation.

In addition to cleaning, lubrication is key to keeping your wire pointing machine running smoothly. Proper lubrication reduces friction between moving parts, preventing wear and tear. Be sure to use the recommended lubricant for your machine and apply it to all moving components, such as bearings, gears, and shafts. Check the lubrication levels regularly and top up as needed to ensure optimal performance.

Another important maintenance task is inspecting the machine for any signs of wear or damage. Check the pointing dies for wear and replace them if necessary. Inspect the wire guides and rollers for any signs of damage or misalignment, as these can affect the wire pointing process. If you notice any issues, address them promptly to prevent further damage to the machine.

Regular calibration is also essential for maintaining the accuracy of your wire pointing machine. Over time, the machine’s settings may drift, leading to inaccuracies in wire pointing. Periodically check and adjust the machine’s calibration to ensure that it is pointing wires correctly. This will help maintain the quality of your wire products and prevent costly rework.

In addition to these maintenance tasks, it is important to follow the manufacturer’s recommended maintenance schedule for your wire pointing machine. This may include regular inspections, cleaning, lubrication, and calibration procedures. By following the manufacturer’s guidelines, you can ensure that your machine operates at its best and avoid unexpected breakdowns.

Lastly, proper training for machine operators is crucial for the maintenance of your wire pointing machine. Ensure that your operators are trained in the proper use and maintenance of the machine to prevent misuse and damage. Regularly review safety procedures with your operators to prevent accidents and ensure the longevity of your machine.

In conclusion, regular maintenance is essential for keeping your wire pointing machine in top condition. By following these maintenance tips, you can prolong the lifespan of your machine, maintain its accuracy, and prevent costly repairs. Remember to clean, lubricate, inspect, calibrate, and follow the manufacturer’s guidelines for maintenance. With proper care and attention, your wire pointing machine will continue to operate efficiently and produce high-quality wire products for years to come.