Showing 1–16 of 27 results

-

This machine is mainly used for straightening and cutting mild steel wire, stainless wire, galvanized wire and all kinds of metal wires. Machine consist of straightening unit, feeding unit, cutting unit. Wire can be load automatically after enters the first feeding roller. This machine has the appropriate design, easy operation, high salability.

-

Barbed Wire Machine is designed to produce screens with single or double-stranded barbed steel wire, zinc. The machine is of horizontal design, consisting of two parts, assembled together at the middle. It is safe and reliable in operation, capable of turning out high quality products with consistency.

-

For cleaning sanding or removing surface defects by means of 2 sanding belts as well as optionally by means of a pressing device 30% more sanding surface than commercially available allows for particularly long sanding belt life and best productivity Suitable for any wire quality Flyer and both sand belt speeds independent and seperate adjustable Noise-proof design on high level Inlet and outfeed sanding belt driven by separate motor (coarse and fine sanding possible) Automatic belt tear control.

-

It is used to drawing and annealing copper rod. In addition, it is applied to making electric wire.

-

Flipper Payoff Stand,The simple horizontal type pay-off stand for dry type wire drawing machine The simple horizontal type pay-offs are particularly recommended for low carbon steel wire or middle carbon steel wire rod with diamter range from 5.5mm to 6.5mm The horizonal pay-off beam and structure is made of a sturdy steel beam with tempered…

-

-

This wire drawing machine is also called Vertical type drawing machine, is widely used in high carbon steel wire (SAE1060, SAE1072, SAE1072, SAW1080, SAE1082) or middle carbon steel wire production, such spring wires, core wire, bead wire, PC wire, bearing wire, wire rope etc.

-

Aluminum wire breakdown drawing machine for cable aluminum wire, aluminum alloy wire, thermal spraying wire

The completely equipment included,

- Pay off stand;

- Drawing machine (main machine);

- ZWS- type spool take up unit;

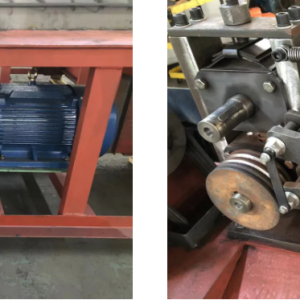

- electric motor for drawing machine;

- Electrical cabinet.

- Operator platform

- Tension frame

-

Non-stop dead block coiler

- Drum sizes : diameter 300mm~1100mm, the customers could chose the different size.

- Adopt the frequency conversion motor controller, inch movement, continued movement, with pedal switch control.

- Cooling system : Internal Drum and Die Box, both have the water cooling system. This equipment is using the wind cooling system.

- Provide the X, Y direction straight wheel, adjustable liner and fence ranges.

-

The complete line machinery consisted of payoff stand, mechanical descaler, OTO type wire drawing, and the coiler.

-

-

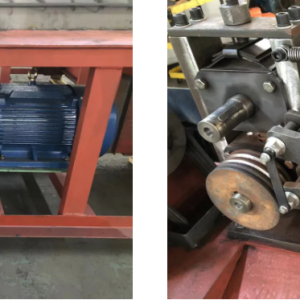

how does the Rotating Die Holder work in the drawing machine?

The die box is equipped with a compartment for the dry or wet soap drawing lubrication and a rotating cooling body for the die. The soapbox can be customized, in either square or round shape, depending on each customers’ requirements. However, Lämneå Bruk does recommend the round shape as it allows the wire to be covered in more soap.

-

Features

- High-Speed Double Head design for perfect abrasive sanding at speeds up to 3.0 m/s.

- SDJ-1310 descalers are designed for low, medium, high carbon and stainless-steel rod.

- Rod inlet diameter from 4.75 up to 12mm Modular construction for ease of instruction.

- Multiple units may be installed in-line for progressive rod surface finish applications.

- Quick sanding belt change by single action lever.

- Operator friendly control panel and convenient access doors for superior productivity and ease of use.

- Supplied with dust collector.

-

Wire rods are covered with an oxide layer, which must be removed before wire drawing.These machines are integrated with the wire drawing line and are widely used for the production of clean surfaced wires and for the purpose of increasing the wire drawing performance.

-

It is composed of a sturdy welded steel structure with horizontal forming head designed to collect drawn wire on vertical stems (spider reels). The structure, which is totally closed for noise and safety aspects, is designed to contain all the mechanical transmission as well as the main motor.

-

This wire drawing machine is also called Straight line drawing machine, is widely used in high carbon steel wire (SAE1060, SAE1072, SAE1072, SAW1080, SAE1082) or middle carbon steel wire production, such spring wires, MIG welding wire, CO2 welding wire(ER70S-6, SG-2), SS wire, SAW welding wire, core wire, bead wire, PC wire, bearing wire, wire rope etc.