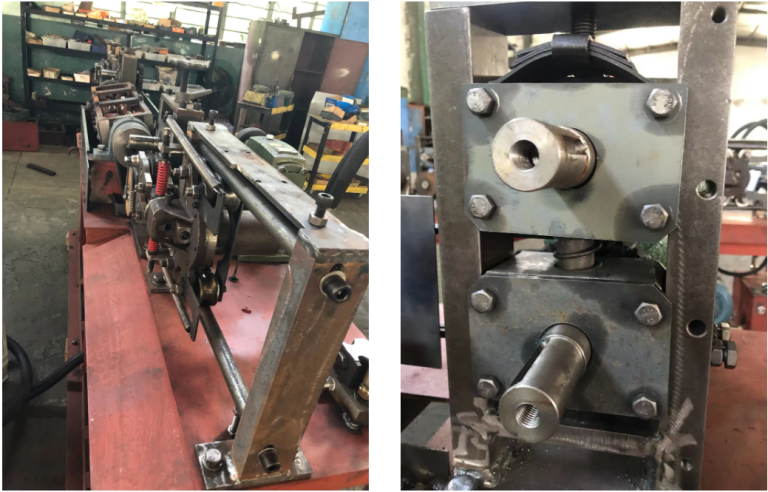

آلة ==u0633===u0628 =u0623سلاك الألمنيوم LLT-17/400إن آلة =u0633===u0628 =u0623سلاك الألمنيوم ЛТ-17/400 هي قطعة مهمة من المعدات في صناعة تصنيع الأسلاك。 لضمان عمل هذه الآلة بكفاءة وفعالية، تعد الصيانة الدورية أمرًا ضروريا。 في هذه المقالة، سنناقش بعض نصائ= = ==u0627لصيانة الأساسية لآلة =u0633=== أسلاك الألمنيوم ЛЛТ-17/400 لكابلات أسلاك الألمنيوم.

أولًا وقبل كل شيء، من المهم = =u0641====u0627لماكينة بانتظام بحث ًا عن أي علامات تآكل。 يتضمن ذلك التحقق من الأجزاء السائبة أو التالفة، بالإضافة إلى التأكد من تشحيم جميع المكونات =================================================== == =================== =================================================== == ==================

بالإضافة إلى عمليات الفحص المنتظمة، من المهم أيضًا تنظيف الجهاز بشكل منتظم。 يمكن أن يتراكم الغبار والأوسا

نصيحة صيانة مهمة أخرى لـ

マッキーナهو معايرة الجهاز بانتظام。 تضمن المعايرة أن الجهاز يعمل بالمستوى الأمثل ويمكن أن يساعد في منع =وث مشكلات مثل سمك السلك غير المتساوي أو الكسر。 ومن من المهم أيضًا الانتباه إلى المكونات الكهربائية بالجهاز。 مع مرور الوقت، يمكن أن تصبح التوصيلات الكهربائية مفككة أو متآكلة، مما قد يؤدي إلى =دوث أعطال。 من بالإضافة إلى ذلك، من المهم اتباع إرشادات الشركة المصنعة فيما يتعلق بالصيانة والخدمة。 توفر إرشادات الشركة المصنعة معلومات قيمة =ول كيفية العناية بالجهاز بشكل صحيح ويمكن أن تساعد في إطالة عمره الافتراضي。 باتباع هذه الإرشادات، يمكنك التأكد من استمرار الجهاز في

وأخيرًا، من المهم الاحتفاظ بسجلات تفصيلية لتاريخ صيانة الجهاز。 من خلال تتبع وقت تنفيذ مهام الصيانة وأي مشكلات تم تحديدها، يمكنك تتبع أداء الجهاز بشكل أفضل بمرور الوقت。 يمكن أن تكون هذه المعلومات أيضًا ذات قيمة لتحديد الأنماط أو الاتجاهات التي قد تشير إلى المشكلات الأساسية بالجهاز.

في الختام، تعد الصيانة المناسبة أمرًا ضروريًا لضمان طول عمر وأداء ماكينة سحب أسلاك الألومنيوم LLT-17/400。 من

في الختام، تعد الصيانة المناسبة أمرًا ضروريًا لضمان طول عمر وأداء ماكينة سحب أسلاك الألومنيوم LLT-17/400。 من

في الختام، تعد الصيانة المناسبة أمرًا ضروريًا لضمان طول عمر وأداء ماكينة سحب أسلاك الألومنيوم LLT-17/400。 من خلال إجراء عمليات فحص منتظمة، وتنظيف الجهاز، ومعايرته بانتظام، وفحص المكونات الكهربائية، واتباع إرشادات الشركة المصنعة، والاحتفاظ بسجلات مفصلة، يمكنك المساعدة في منع المشكلات والتأكد من استمرار الجهاز في العمل بأفضل حالاته。 باتباع نصائح الصيانة هذه، يمكنك المساعدة في تحقيق أقصى قدر من الكفاءة والفعالية لآلة سحب أسلاك الألمنيوم LLT-17/400.