Understand The Benefits of Using Steel Brush Descaler in Wire Drawing Process

The wire drawing process is a crucial step in the production of various wire products, such as electrical wiring, fencing, and cables. This process involves pulling a metal wire through a series of dies to reduce its diameter and improve its mechanical properties. However, during the wire drawing process, the wire can accumulate scale, rust, and other contaminants on its surface, which can negatively impact the quality of the final product. To address this issue, many manufacturers use steel brush descalers to clean and prepare the wire before it undergoes further processing.

One of the key benefits of using a steel brush descaler in the wire drawing process is its ability to effectively remove scale and other contaminants from the surface of the wire. Scale is a layer of oxide that forms on the surface of metal products during the manufacturing process. If not removed, scale can cause surface defects, reduce the wire’s ductility, and compromise its mechanical properties. By using a steel brush descaler, manufacturers can easily remove scale and other contaminants from the wire, ensuring that it meets the required quality standards.

In addition to removing scale, a Mechanical brush descaler can also improve the surface finish of the wire. The abrasive action of the steel brushes helps to smooth out any rough spots or imperfections on the wire’s surface, resulting in a cleaner and more uniform finish. This is particularly important for wire products that require a high level of precision and consistency, such as electrical wiring or medical devices. By using a steel brush descaler, manufacturers can ensure that their wire products meet the strict quality standards demanded by their customers.

Another benefit of using a steel brush descaler in the wire drawing process is its ability to increase the efficiency of the production line. By removing scale and other contaminants from the wire before it undergoes further processing, manufacturers can reduce the risk of equipment damage and downtime. This can help to improve overall productivity and reduce production costs. Additionally, a steel brush descaler can help to extend the lifespan of the wire drawing dies by preventing them from becoming clogged or damaged by scale buildup.

Furthermore, using a steel brush descaler can also help to improve the safety of the wire drawing process. Scale and other contaminants on the surface of the wire can create safety hazards for workers, as they can cause slips, trips, and falls. By using a steel brush descaler to clean the wire before it enters the production line, manufacturers can create a safer working environment for their employees. This can help to reduce the risk of accidents and injuries, leading to a more efficient and productive workplace.

Overall, the benefits of using a steel brush descaler in the wire drawing process are clear. From improving the quality of the final product to increasing efficiency and safety in the production line, a steel brush descaler is an essential tool for manufacturers looking to achieve the highest standards of quality and performance. By investing in a steel brush descaler, manufacturers can ensure that their wire products meet the demands of their customers and remain competitive in the market.

How to Choose the Right Steel Brush Descaler for Wire Drawing Operations

Wire drawing is a process used in various industries to reduce the diameter of a wire by pulling it through a series of dies. This process is essential for producing wires of different sizes and shapes for applications such as electrical wiring, cables, and springs. However, during the wire drawing process, the wire can accumulate scale, rust, and other contaminants that can affect the quality of the final product. To remove these impurities and ensure a smooth wire drawing operation, a Steel Brush Descaler For Wire Drawing Process is often used.

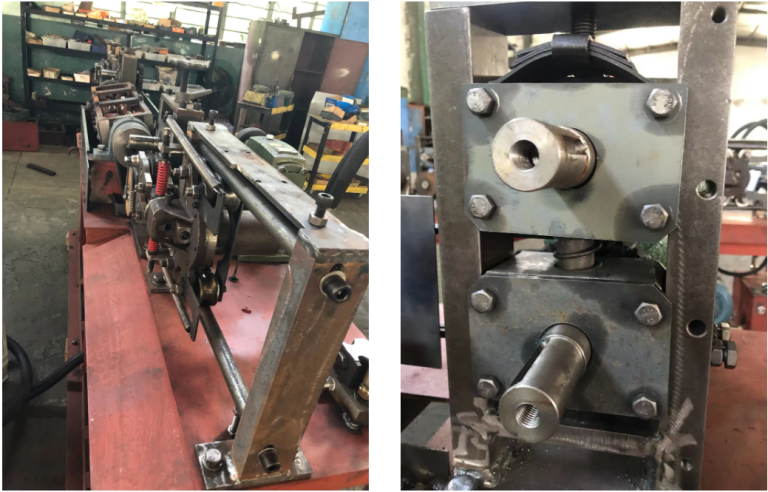

A steel brush descaler is a tool specifically designed to remove scale, rust, and other contaminants from the surface of the wire before it enters the drawing dies. This helps to improve the quality of the wire and prolong the life of the drawing dies. When choosing a steel brush descaler for wire drawing operations, there are several factors to consider to ensure that you select the right tool for your specific needs.

One of the most important factors to consider when choosing a steel brush descaler is the type of wire you will be processing. Different types of wire require different types of descalers to effectively remove scale and contaminants. For example, if you are processing stainless steel wire, you will need a descaler with stainless steel brushes to prevent contamination. On the other hand, if you are processing carbon steel wire, a descaler with carbon steel brushes may be more suitable.

Another important factor to consider is the size and speed of the wire drawing operation. The size of the wire and the speed at which it is being drawn will determine the size and power of the steel brush descaler needed. For high-speed wire drawing operations, a descaler with a powerful motor and large brushes may be required to effectively remove scale and contaminants. Additionally, the size of the wire will determine the size of the brushes needed to ensure thorough cleaning.

It is also important to consider the maintenance requirements of the steel brush descaler. Regular maintenance is essential to ensure that the descaler continues to operate effectively and prolong its lifespan. Some descalers may require more frequent maintenance, such as replacing brushes or cleaning out debris, while others may be more low-maintenance. Consider the maintenance requirements of the descaler when making your selection to ensure that it fits within your maintenance schedule and budget.

In addition to these factors, it is important to consider the reputation and reliability of the manufacturer when choosing a steel brush descaler. Look for a manufacturer with a proven track record of producing high-quality descalers that are durable and reliable. Reading reviews and testimonials from other users can also help you gauge the performance and reliability of a particular descaler.

In conclusion, choosing the right steel brush descaler for wire drawing operations is essential to ensure a smooth and efficient process. Consider factors such as the type of wire being processed, the size and speed of the operation, maintenance requirements, and the reputation of the manufacturer when making your selection. By carefully considering these factors, you can choose a steel brush descaler that meets your specific needs and helps to improve the quality of your wire drawing operations.