Advantages of Using Inverted Vertical Wire Drawing Machines

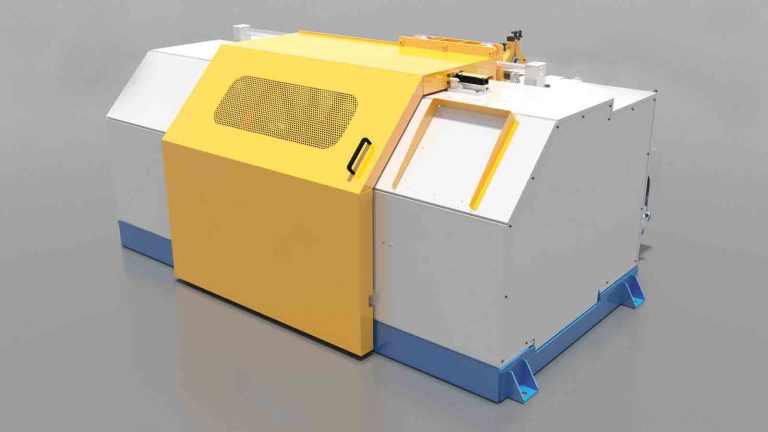

Inverted Vertical Single Block wire drawing machine is a type of wire drawing equipment that offers several advantages over traditional horizontal machines. These machines are designed to draw wire vertically, with the wire passing through a series of dies to reduce its diameter. This unique design offers a number of benefits that make inverted vertical wire drawing machines a popular choice for many industries.

One of the key advantages of using inverted vertical wire drawing machines is their compact size. These machines take up less floor space compared to horizontal machines, making them ideal for facilities with limited space. This compact design also allows for easier installation and maintenance, as the machines can be easily accessed from all sides.

In addition to their small footprint, inverted vertical wire drawing machines offer improved wire quality. The vertical orientation of the machines allows for better control over the drawing process, resulting in a more uniform wire diameter and smoother surface finish. This can lead to higher quality end products and reduced scrap rates, ultimately saving time and money for manufacturers.

Another advantage of using inverted vertical wire drawing machines is their versatility. These machines can be used to draw a wide range of wire sizes and materials, making them suitable for a variety of applications. Whether you need to draw thin copper wire for electronics or thick steel wire for construction, inverted vertical wire drawing machines can handle the job with ease.

Furthermore, inverted vertical wire drawing machines are known for their energy efficiency. The vertical orientation of the machines allows for better heat dissipation, reducing the risk of overheating and prolonging the life of the equipment. This can result in lower energy costs and reduced downtime, making inverted vertical wire drawing machines a cost-effective choice for manufacturers.

Inverted vertical wire drawing machines also offer improved operator safety. The vertical design of the machines allows for better visibility and access to the Wire Drawing Process, reducing the risk of accidents and injuries. Additionally, many inverted vertical wire drawing machines are equipped with safety features such as emergency stop buttons and protective guards to further enhance operator safety.

Overall, inverted vertical wire drawing machines offer a number of advantages that make them a popular choice for manufacturers in a variety of industries. From their compact size and improved wire quality to their versatility and energy efficiency, these machines provide a cost-effective and safe solution for wire drawing operations. Whether you are looking to upgrade your existing equipment or invest in new Wire drawing Machinery, inverted vertical wire drawing machines are worth considering for your manufacturing needs.

Tips for Maintaining and Troubleshooting Inverted Vertical Wire Drawing Machines

Inverted vertical wire drawing machines are essential equipment in the wire manufacturing industry. These machines are used to draw wire through a series of dies to reduce its diameter and improve its quality. Proper maintenance and troubleshooting of these machines are crucial to ensure smooth operation and prevent costly downtime.

One of the key tips for maintaining inverted Vertical Type Drawing Machine is regular lubrication. Proper lubrication of the machine’s moving parts, such as the drawing dies and rollers, helps reduce friction and wear, extending the machine’s lifespan. It is important to use the correct type of lubricant recommended by the manufacturer and to follow the recommended lubrication schedule.

In addition to lubrication, regular inspection of the machine’s components is essential for detecting any signs of wear or damage. Inspecting the drawing dies, rollers, and other parts for signs of wear, such as cracks or deformation, can help prevent unexpected breakdowns and ensure the machine’s optimal performance. Any worn or damaged parts should be replaced promptly to avoid further damage to the machine.

Another important aspect of maintaining inverted vertical wire drawing machines is proper tension control. Tension control is crucial for achieving the desired wire diameter and quality during the drawing process. Improper tension can lead to wire breakage, uneven drawing, and other quality issues. Regularly checking and adjusting the tension settings on the machine can help ensure consistent and high-quality wire production.

In addition to regular maintenance, troubleshooting inverted vertical wire drawing machines is essential for identifying and resolving any issues that may arise during operation. One common issue with these machines is wire breakage. Wire breakage can be caused by various factors, such as improper tension, worn drawing dies, or misalignment of the machine’s components. Troubleshooting wire breakage involves identifying the root cause of the issue and taking appropriate corrective actions, such as adjusting the tension settings or replacing worn parts.

Another common issue with inverted vertical wire drawing machines is uneven drawing. Uneven drawing can result in wire with inconsistent diameter and quality. Troubleshooting uneven drawing involves checking the alignment of the machine’s components, inspecting the drawing dies for wear, and adjusting the tension settings to ensure uniform drawing. Regularly monitoring the wire quality during production can help detect any issues with uneven drawing early on and prevent costly rework.

In conclusion, maintaining and troubleshooting inverted vertical wire drawing machines is essential for ensuring smooth operation and high-quality wire production. Regular lubrication, inspection of machine components, proper tension control, and timely troubleshooting of issues are key aspects of machine maintenance. By following these tips, wire manufacturers can maximize the performance and lifespan of their inverted vertical wire drawing machines, leading to improved productivity and profitability.