Streamlining Production With A State-Of-The-Art Steel Nail Makking Machine

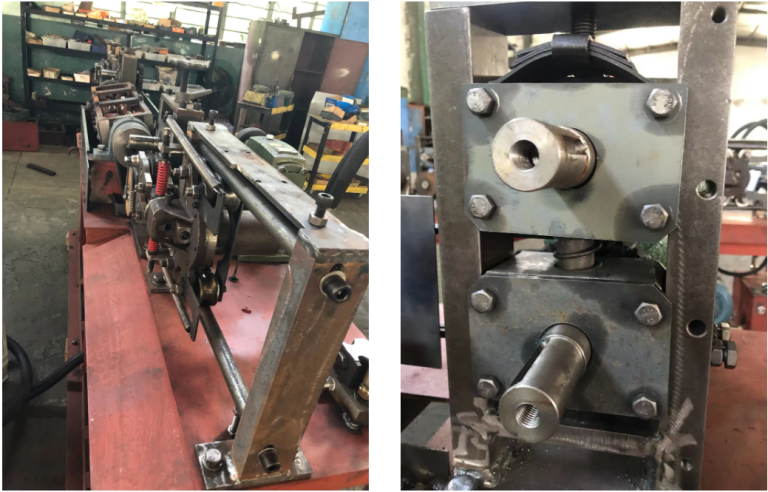

One way to streamline production processes is by investing in state-of-the-art equipment, such as a Steel Wire Nail Making Machine. This cutting-edge technology can revolutionize the way steel nails are produced, making the process faster, more accurate, and more cost-effective.

One of the main advantages of a steel nail automatic machine is its ability to produce a large volume of nails in a short amount of time. Traditional nail production methods can be time-consuming and labor-intensive, requiring skilled workers to manually feed, cut, and shape each nail. With an automatic machine, the entire process is automated, allowing for continuous production without the need for constant supervision. This not only increases output but also reduces the risk of human error, resulting in higher-quality nails.

Furthermore, a automatic wire nail making machine is equipped with advanced technology that ensures precision and consistency in nail production. Each nail is cut to the exact length and shape specified, resulting in uniform nails that meet industry standards. This level of accuracy is crucial in industries where nails are used for construction, carpentry, or other applications where precision is essential. By using an automatic machine, manufacturers can guarantee that every nail produced is of the highest quality.

Another benefit of a steel nail making machines are its cost-effectiveness. While the initial investment in this technology may be significant, the long-term savings can be substantial. By increasing production efficiency and reducing labor costs, manufacturers can lower their overall production expenses and increase their profit margins.

In addition to its efficiency and cost-effectiveness, a automatic wire nail making machine also offers versatility in nail production. These machines can be programmed to produce nails of various sizes, shapes, and materials, allowing manufacturers to meet the specific needs of their customers. Whether producing standard nails for general construction or specialty nails for specific applications, an automatic machine can adapt to changing production requirements with ease.

Overall, investing in a steel nail automatic machine can have a significant impact on a manufacturer’s production processes. By increasing efficiency, precision, and cost-effectiveness, this technology can help companies stay competitive in today’s fast-paced market. With its ability to produce high-quality nails in large volumes, an automatic machine is a valuable asset for any manufacturer looking to streamline their production processes and improve their bottom line.