Understand of Using GI Wire in Construction Projects

Galvanized iron (GI) wire is a popular choice in construction projects due to its durability and strength. It is made by coating iron or steel wire with a layer of zinc, which helps protect it from corrosion and rust. GI wire is commonly used in various applications, such as fencing, binding, and reinforcement in concrete structures. In this article, we will explore the benefits of using GI wire in construction projects.

One of the main advantages of using GI wire is its resistance to corrosion. The zinc coating on the wire acts as a barrier, preventing moisture and other corrosive elements from reaching the underlying metal. This helps extend the lifespan of the wire and ensures that it remains strong and reliable over time. As a result, structures built with GI Wire Production Line are less likely to deteriorate or require frequent maintenance.

In addition to its corrosion resistance, GI wire is also known for its high tensile strength. This means that it can withstand heavy loads and stresses without breaking or deforming. This makes it an ideal choice for applications where strength and durability are essential, such as in the construction of bridges, buildings, and other infrastructure projects. GI wire is also flexible and easy to work with, making it suitable for a wide range of construction tasks.

Another benefit of using GI wire is its cost-effectiveness. While the initial cost of GI wire may be slightly higher than other types of wire, its long-term durability and low maintenance requirements make it a cost-effective choice in the long run. By using GI wire, construction projects can save money on repairs and replacements, as well as reduce the need for ongoing maintenance.

Furthermore, GI wire is environmentally friendly. The zinc coating on the wire is recyclable, making it a sustainable choice for construction projects. By using GI wire, builders can reduce their environmental impact and contribute to a more sustainable construction industry. Additionally, the durability of GI wire means that it can be reused or repurposed in future projects, further reducing waste and promoting sustainability.

In conclusion, GI wire offers a range of benefits for construction projects, including corrosion resistance, high tensile strength, cost-effectiveness, and environmental sustainability. By using GI wire, builders can create strong, durable structures that stand the test of time while also reducing their environmental impact. With its versatility and reliability, GI wire is a valuable asset in the construction industry and a key component in the production line of any factory.

How to Choose the Right GI Wire Production Line for Your Factory

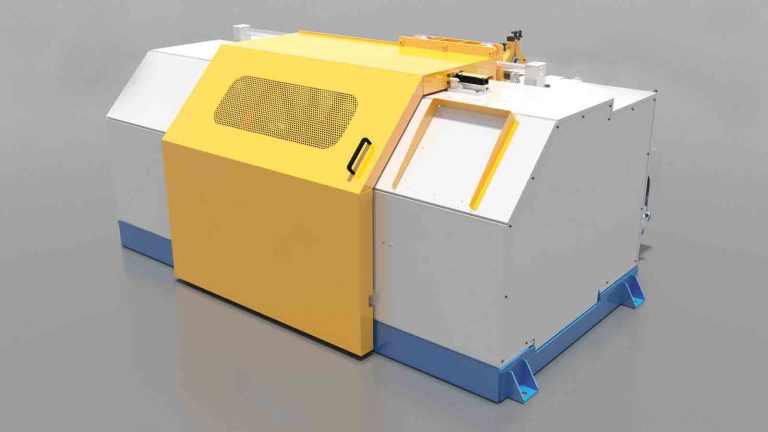

When it comes to setting up a GI wire production line in your factory, choosing the right equipment is crucial for ensuring efficiency and quality in your manufacturing process. With so many options available in the market, it can be overwhelming to make the right decision. In this article, we will discuss some key factors to consider when selecting a GI wire production line for your factory.

First and foremost, it is important to assess your production needs and requirements. Consider factors such as the volume of GI wire you need to produce, the diameter and thickness of the wire, and the quality standards you need to meet. This will help you determine the capacity and specifications of the production line that will best suit your factory.

Next, consider the technology and features offered by different GI wire production lines. Look for equipment that is equipped with advanced automation and control systems, as well as safety features to ensure smooth operation and minimize downtime. Additionally, consider the flexibility and scalability of the production line, as you may need to expand or modify your manufacturing process in the future.

Another important factor to consider is the reputation and reliability of the manufacturer. Look for a reputable supplier with a proven track record in the industry and positive customer reviews. A reliable manufacturer will not only provide you with high-quality equipment but also offer excellent after-sales support and maintenance services.

Cost is also a crucial consideration when choosing a GI wire production line for your factory. While it is important to stay within budget, it is equally important to invest in quality equipment that will deliver long-term value. Consider the total cost of ownership, including maintenance and operating costs, when evaluating different options.

Furthermore, consider the space and layout of your factory when selecting a GI wire production line. Ensure that the equipment will fit comfortably in your production area and allow for efficient workflow. Consider factors such as accessibility for maintenance and ease of material handling when designing your production line layout.

Lastly, consider the environmental impact of the production line. Look for equipment that is energy-efficient and environmentally friendly, as this will not only reduce your carbon footprint but also lower operating costs in the long run. Consider investing in equipment that is certified for energy efficiency and sustainability.

In conclusion, choosing the right GI wire production line for your factory is a critical decision that requires careful consideration of various factors. By assessing your production needs, evaluating technology and features, considering the reputation of the manufacturer, weighing the cost, and considering space and environmental factors, you can make an informed decision that will benefit your factory in the long run. Remember to consult with industry experts and suppliers to help you make the best choice for your manufacturing process.

The Importance of Quality Control in GI Wire Manufacturing Process

Quality control is a crucial aspect of any manufacturing process, and this holds true for the production of GI wire as well. GI wire, or galvanized iron wire, is a type of wire that is coated with a layer of zinc to protect it from corrosion. It is commonly used in a variety of applications, including construction, agriculture, and fencing. In order to ensure that the GI wire meets the required standards and specifications, it is essential to implement a rigorous quality control process throughout the manufacturing process.

One of the key steps in the production of GI wire is the galvanizing process, where the wire is coated with a layer of zinc. This process is critical to the performance and durability of the wire, as the zinc coating provides protection against corrosion. However, if the galvanizing process is not carried out properly, it can result in a substandard product that is prone to rust and corrosion. This is why it is important to closely monitor and control the galvanizing process to ensure that the wire meets the required quality standards.

In addition to the galvanizing process, there are several other factors that can impact the quality of GI wire. For example, the quality of the raw materials used in the production process can have a significant impact on the final product. If the raw materials are of poor quality, it can result in a substandard product that does not meet the required specifications. This is why it is important to carefully select and test the raw materials before they are used in the production process.

Furthermore, the production process itself can also impact the quality of the GI wire. For example, if the wire is not properly drawn or annealed, it can result in a product that is brittle and prone to breakage. Similarly, if the wire is not properly wire drawing machine For Zinc Coating GI Wire with zinc during the galvanizing process, it can result in a product that is not adequately protected against corrosion. This is why it is important to closely monitor and control each step of the production process to ensure that the wire meets the required quality standards.

To ensure that the GI wire meets the required quality standards, it is essential to implement a comprehensive quality control process throughout the manufacturing process. This process should include regular testing and inspection of the raw materials, as well as monitoring and control of each step of the production process. In addition, it is important to conduct thorough testing of the final product to ensure that it meets the required specifications.

By implementing a rigorous quality control process, manufacturers can ensure that their GI wire meets the required quality standards and specifications. This not only helps to ensure the performance and durability of the wire but also helps to build trust and confidence with customers. In today’s competitive market, quality control is more important than ever, and manufacturers who prioritize quality control are more likely to succeed in the long run.

In conclusion, quality control is a critical aspect of the GI wire manufacturing process. By closely monitoring and controlling each step of the production process, manufacturers can ensure that their GI wire meets the required quality standards and specifications. This not only helps to ensure the performance and durability of the wire but also helps to build trust and confidence with customers. In today’s competitive market, quality control is essential for success, and manufacturers who prioritize quality control are more likely to thrive in the long term.