Showing 17–26 of 26 results

-

It is composed of a sturdy welded steel structure with horizontal forming head designed to collect drawn wire on vertical stems (spider reels). The structure, which is totally closed for noise and safety aspects, is designed to contain all the mechanical transmission as well as the main motor.

-

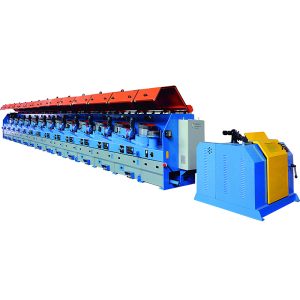

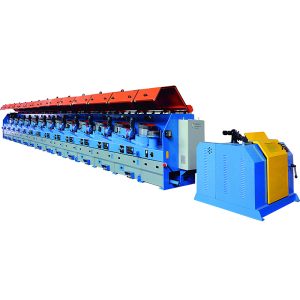

This wire drawing machine is also called Straight line drawing machine, is widely used in high carbon steel wire (SAE1060, SAE1072, SAE1072, SAW1080, SAE1082) or middle carbon steel wire production, such spring wires, MIG welding wire, CO2 welding wire(ER70S-6, SG-2), SS wire, SAW welding wire, core wire, bead wire, PC wire, bearing wire, wire rope etc.

-

It is suitable for all kinds of metal.

Cooling system : internal Drum and Die Box, both have the cooling system.

Drum : after multiple materials treatment and processing, the surface of Drum has the mirror treatment, and it can efficiently prevent wire surface scratch. It is durable, and a long life as well.

Human-Machine Interface Digital Control System & Industry 4.0 :

Electric control system provides a smooth acceleration from zero to the pre-selected value. Monitoring at office with MIS system by connecting the networks. It also could be monitored by the smart phone. Remote connection through modem allows On-line trouble shooting by Engineers.

Gear Box : gears are suitable for long time operating with high load. Long lifetime due to the surface of gears grinded based on grade 2 of JIS standard.

-

- It is suitable for all kinds of metal.

- Cooling system : internal Drum and Die Box, both have the cooling system.

- Drum : after multiple materials treatment and processing, the surface of Drum has the mirror treatment, and it can efficiently prevent wire surface scratch. It is durable, and a long life as well.

- Human-Machine Interface Digital Control System & Industry 4.0 :

- Electric control system provides a smooth acceleration from zero to the pre-selected value. Monitoring at office with MIS system by connecting the networks. It also could be monitored by the smart phone. Remote connection through modem allows On-line trouble shooting by Engineers.

- Gear Box : gears are suitable for long time operating with high load.

-

Water Tank Type Wire Drawing machine is a small branch of the wire drawing machine, it is mainly used for binding wire, chain link fence and galvanized wire manufacture.

-

Wire Butt Welding Machine

Majority of wires are welded on this type of medium-duty resistance butt welding machines. Elegant design, automatic upset, precise movement pattern, and foot pedal operation make this machine a definite winner over our competitors. More economy and productivity can be achieved by adding optional accessories. As a market leader, our technical expertise, and know-how of end applications deliver these cost-effective machines for long-lasting equipment life.

-

Mechanical descaling removal is to use of mechanical methods to remove oxides on the surface of wire rods and process them into a state suitable for subsequent drawing.

-

Wire pointer and string-up of drawing dies

Pull-in capstan individually powered

String-up multiple dies at once

Precision hardened and ground forming rollers

Various diameter working range available

Quiet and minimal vibration operation

Safe and easy to use

Wire cutting equipment available

-

-

Suitable to wind carbon steel wires onto reeles with flanges having a diameter from 500-1000 mm

Sturdy frame in electrowelded steel

Pneumatic lifter for reel loading and unloading

Tailstock with pnuematic drive and mechanic lock

Front control panel

Max capacity of reeels tht can be used up to 2000 Kg

Range of wire diameters to be wound from 0.6-7 mm

Max lineer winding speed up to 20 m/s