Exploring Of Using Thermal Spraying Wire For Industrial Coating Applications

Thermal spraying wire is a versatile and effective method for applying coatings to various industrial surfaces. This process involves melting a wire material and spraying it onto a substrate to create a protective or decorative coating. There are several benefits to using thermal spraying wire for industrial coating applications, making it a popular choice for many industries.

One of the main advantages of thermal spraying wire is its ability to provide a durable and long-lasting coating. The high temperatures involved in the spraying process allow the wire material to bond tightly to the substrate, creating a strong and resilient coating that can withstand harsh environmental conditions. This makes thermal spraying wire ideal for applications where durability and longevity are essential, such as in the aerospace, automotive, and oil and gas industries.

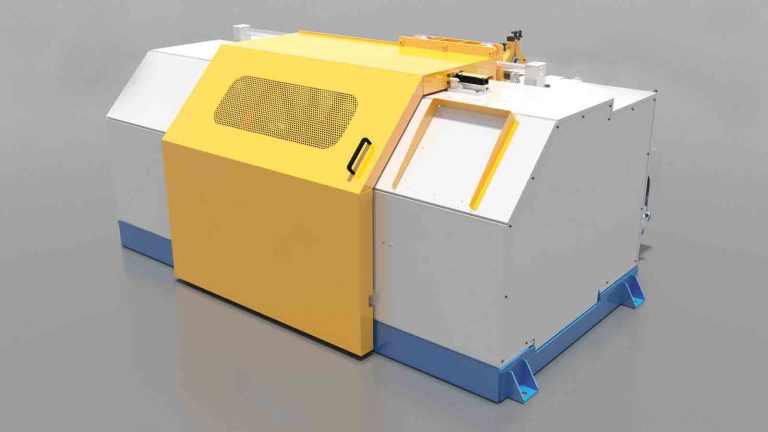

In addition to its durability,Aluminum Alloy Wire machine also offers excellent corrosion resistance. The protective coating created by the spraying process acts as a barrier between the substrate and the surrounding environment, preventing corrosion and extending the lifespan of the coated surface. This is particularly important in industries where equipment is exposed to corrosive substances or harsh weather conditions, as it helps to prevent costly damage and downtime.

Another benefit of using thermal spraying wire is its versatility. There are a wide variety of wire materials available for thermal spraying, including metals, ceramics, and polymers, allowing for customization based on the specific requirements of the application. This flexibility makes thermal spraying wire suitable for a wide range of industrial coating applications, from providing wear resistance on machine parts to creating decorative finishes on architectural structures.

Furthermore, thermal spraying wire is a cost-effective coating solution. The process is relatively quick and efficient, requiring minimal preparation and downtime compared to other coating methods. This can result in significant cost savings for industries looking to protect their equipment and infrastructure without breaking the bank. Additionally, the durability and longevity of thermal spraying wire coatings mean that they require less frequent maintenance and replacement, further reducing overall costs in the long run.

In conclusion, thermal spraying wire offers a range of benefits for industrial coating applications. From its durability and corrosion resistance to its versatility and cost-effectiveness, thermal spraying wire is a reliable and efficient method for protecting and enhancing industrial surfaces. Whether you are looking to extend the lifespan of your equipment, improve its performance, or simply enhance its appearance, thermal spraying wire is a proven solution that can meet your needs. Consider incorporating thermal spraying wire into your industrial coating processes to experience the many advantages it has to offer.