Advanteges Of Using A Wire descaling machine

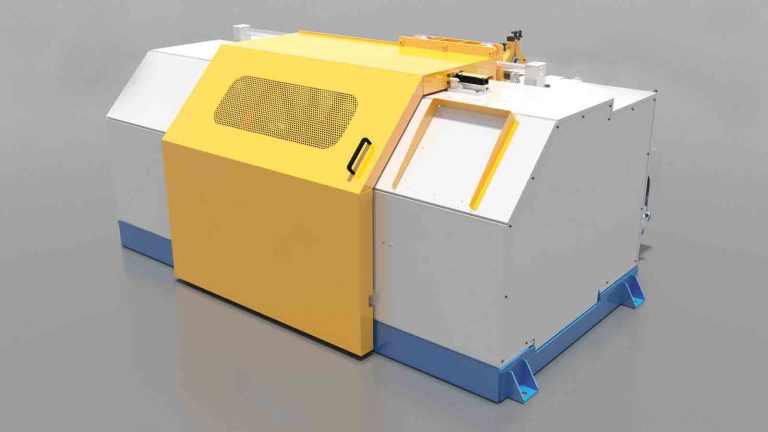

Wire descaling machines are essential tools in various industries that rely on wire production. These machines are designed to remove scale, rust, and other impurities from wire surfaces, ensuring a smooth and clean finish. In this article, we will explore the benefits of using a wire descaling machine in your production process.

One of the primary benefits of using a Wire Rod Descaling Machine is the improved quality of the finished product. By removing scale and other impurities from the wire surface, the machine helps to create a smooth and clean finish that is free from defects. This not only enhances the appearance of the wire but also improves its performance and durability.

In addition to improving the quality of the finished product, a wire descaling machine also helps to increase productivity in the production process. By automating the descaling process, the machine can descale wire at a much faster rate than manual methods, allowing for higher production volumes and faster turnaround times. This can help to reduce production costs and increase overall efficiency in the production process.

Another benefit of using a wire descaling machine is the reduction of waste and scrap in the production process. By removing scale and other impurities from the wire surface, the machine helps to minimize the risk of defects and imperfections in the finished product. This can help to reduce the amount of waste and scrap produced during the production process, leading to cost savings and improved sustainability.

Furthermore, a wire descaling machine can help to extend the lifespan of production equipment. Scale and other impurities on wire surfaces can cause wear and tear on production equipment, leading to increased maintenance costs and downtime. By removing these impurities, the machine helps to protect production equipment from damage and prolong its lifespan, saving money on repairs and replacements in the long run.

Additionally, using a wire descaling machine can help to improve workplace safety. Manual descaling methods can be labor-intensive and potentially hazardous, exposing workers to risks of injury and fatigue. By automating the descaling process, the machine helps to reduce the need for manual labor and minimize the risks associated with manual descaling methods, creating a safer working environment for employees.

Overall, the benefits of using a wire descaling machine in your production process are clear. From improving the quality of the finished product to increasing productivity, reducing waste, extending equipment lifespan, and enhancing workplace safety, a wire descaling machine can have a significant impact on your production process. Consider investing in a wire descaling machine today to experience these benefits for yourself and take your wire production to the next level.