Key Factors to Consider When Setting Up a GI Wire Production Line

Setting up a GI wire production line requires careful planning and consideration of several key factors. From selecting the right equipment to ensuring efficient production processes, there are many aspects to take into account when establishing a successful production line. In this article, we will discuss some of the key factors that should be considered when setting up a GI wire production line.

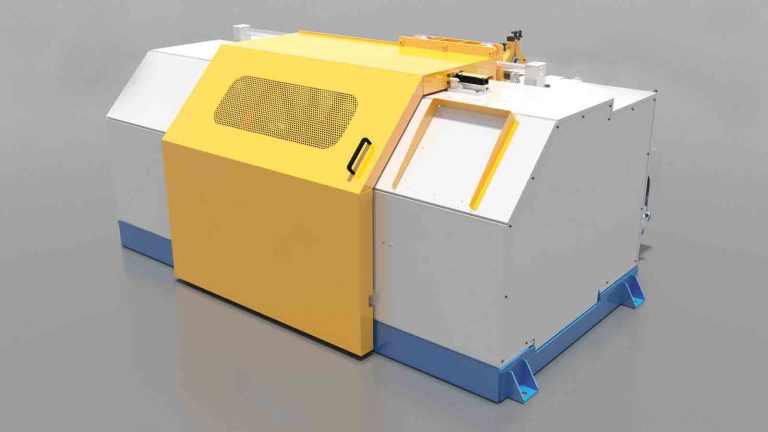

One of the first things to consider when setting up a GI wire production line is the type of equipment that will be needed. This includes machinery for wire drawing, galvanizing, and coiling, as well as any additional equipment such as annealing furnaces or spooling machines. It is important to choose equipment that is reliable, efficient, and capable of meeting the production requirements of the business.

Another important factor to consider is the layout of the production line. The layout should be designed to optimize workflow and minimize downtime. This includes ensuring that there is enough space for each piece of equipment, as well as efficient material handling systems to move wire from one process to the next. A well-designed layout can help to improve productivity and reduce production costs.

In addition to equipment and layout, it is also important to consider the quality of the raw materials used in the production process. The quality of the GI wire produced will depend on the quality of the raw materials, so it is important to source materials from reputable suppliers. This includes ensuring that the steel used for wire drawing is of high quality and meets the required specifications for galvanizing.

Quality control is another key factor to consider when setting up a GI wire production line. This includes implementing quality control processes at each stage of production to ensure that the finished product meets the required standards. This may include regular testing of wire samples, as well as monitoring production processes to identify any potential issues that could affect product quality.

Efficiency is also an important consideration when setting up a GI wire production line. This includes optimizing production processes to minimize waste and maximize productivity. This may involve implementing lean manufacturing principles, such as reducing setup times or improving material flow, to streamline production and reduce costs.

Finally, it is important to consider the safety of workers when setting up a GI wire production line. This includes ensuring that all equipment meets safety standards and that workers are properly trained in safe operating procedures. It is also important to provide a safe working environment, with proper ventilation and protective equipment to minimize the risk of accidents or injuries.

In conclusion, setting up a GI wire production line requires careful planning and consideration of several key factors. From selecting the right equipment to ensuring efficient production processes, there are many aspects to take into account when establishing a successful production line. By considering these key factors, businesses can set up a GI wire production line that is efficient, cost-effective, and produces high-quality products.

Benefits of Investing in a Modern GI Wire Production Line

In today’s fast-paced and competitive market, it is essential for businesses to stay ahead of the curve by investing in modern and efficient production equipment. One such piece of equipment that can greatly benefit a company is a wire drawing machine For Zinc Coating GI Wire. GI wire, or galvanized iron wire, is a versatile material used in a wide range of industries, including construction, agriculture, and manufacturing. Investing in a modern GI wire production line can offer numerous benefits for businesses looking to improve their production processes and increase their bottom line.

One of the primary benefits of investing in a modern GI wire production line is increased efficiency. Modern production lines are equipped with advanced technology and automation systems that can significantly reduce production time and labor costs. By streamlining the production process and minimizing human error, businesses can produce high-quality GI wire at a faster rate and with greater consistency. This increased efficiency can lead to higher output levels and ultimately, greater profitability for the company.

Another key benefit of a modern GI wire production line is improved product quality. Modern production lines are designed to meet strict quality control standards, ensuring that each batch of GI wire meets the required specifications and standards. By investing in a modern production line, businesses can produce high-quality GI wire that is durable, reliable, and free from defects. This can help businesses build a strong reputation for quality and reliability, leading to increased customer satisfaction and loyalty.

In addition to increased efficiency and improved product quality, investing in a modern GI wire production line can also help businesses reduce their environmental impact. Modern production lines are designed to be energy-efficient and environmentally friendly, using less energy and producing less waste compared to traditional production methods. By investing in a modern production line, businesses can reduce their carbon footprint and contribute to a more sustainable future.

Furthermore, a modern GI wire production line can also offer businesses greater flexibility and versatility in their production processes. Modern production lines are designed to be modular and customizable, allowing businesses to easily adapt to changing market demands and production requirements. Whether businesses need to increase production capacity, change product specifications, or introduce new product lines, a modern production line can easily accommodate these changes, helping businesses stay competitive in a rapidly evolving market.

Overall, investing in a modern GI wire production line can offer numerous benefits for businesses looking to improve their production processes and increase their bottom line. From increased efficiency and improved product quality to reduced environmental impact and greater flexibility, a modern production line can help businesses stay ahead of the curve and achieve long-term success. By investing in the latest technology and equipment, businesses can position themselves as industry leaders and drive growth and innovation in their respective markets.