Common Issues and Troubleshooting Tips for Aluminum Wire Breakdown Drawing Machines

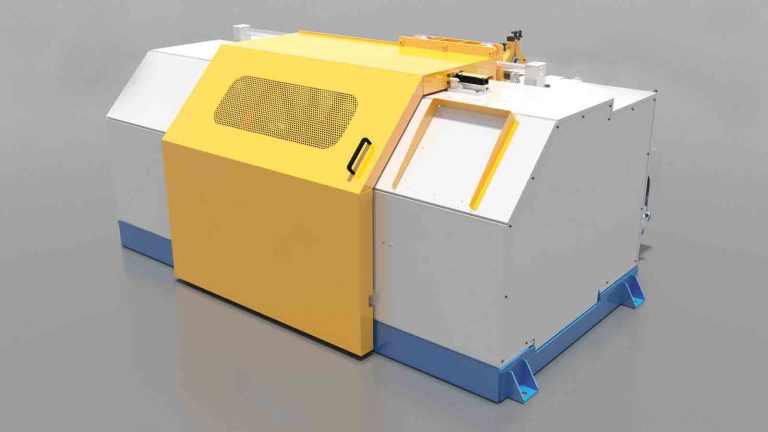

Aluminum wire breakdown drawing machines are essential tools in the manufacturing process of aluminum wire products. These machines are used to reduce the diameter of LLT-17/400 Aluminum Wire Breakdown Drawing Machine by pulling it through a series of dies, resulting in a smoother and more uniform wire. However, like any piece of machinery, breakdown drawing machines can experience common issues that may affect their performance. In this article, we will discuss some of the most common problems that can occur with aluminum wire breakdown drawing machines and provide troubleshooting tips to help resolve them.

One of the most common issues that can occur with aluminum wire breakdown drawing machines is wire breakage. Wire breakage can be caused by a variety of factors, including improper tension settings, worn or damaged dies, or excessive speed. To troubleshoot wire breakage issues, it is important to first check the tension settings on the machine. Adjusting the tension to the correct level can help prevent wire breakage and ensure smooth operation.

Another common issue that can occur with aluminum wire breakdown drawing machines is die wear. Over time, the dies on the machine can become worn or damaged, resulting in poor wire quality and increased breakage. To troubleshoot die wear issues, it is important to regularly inspect the dies for signs of wear and replace them as needed. Keeping the dies clean and properly lubricated can also help extend their lifespan and improve the quality of the wire produced.

In addition to wire breakage and die wear, Aluminum Alloy Wire machine can also experience issues with speed and feed rates. Improper speed and feed settings can result in poor wire quality, uneven diameter reduction, and increased breakage. To troubleshoot speed and feed rate issues, it is important to first check the machine’s operating manual for recommended settings. Adjusting the speed and feed rates to the correct levels can help improve the overall performance of the machine and ensure consistent wire quality.

Another common issue that can occur with aluminum wire breakdown drawing machines is overheating. Overheating can be caused by a variety of factors, including excessive friction, improper lubrication, or a malfunctioning cooling system. To troubleshoot overheating issues, it is important to first check the machine’s cooling system and ensure that it is functioning properly. Keeping the machine well-lubricated and properly maintained can also help prevent overheating and ensure smooth operation.

In conclusion, aluminum wire breakdown drawing machines are essential tools in the manufacturing process of aluminum wire products. However, like any piece of machinery, breakdown drawing machines can experience common issues that may affect their performance. By understanding the common problems that can occur with these machines and following the troubleshooting tips provided in this article, manufacturers can help ensure smooth operation and consistent wire quality. Regular maintenance and proper operation of aluminum wire breakdown drawing machines are key to maximizing their lifespan and efficiency.

Advantages of Using Aluminum Wire Breakdown Drawing Machines

Aluminum wire breakdown drawing machine for cable aluminum wire are essential tools in the wire manufacturing industry. These machines are designed to reduce the diameter of aluminum wire by pulling it through a series of dies, resulting in a thinner and more uniform wire. There are several advantages to using aluminum wire breakdown drawing machines, which make them a popular choice for wire manufacturers.

One of the main advantages of using aluminum wire breakdown drawing machines is the ability to produce high-quality wire with consistent diameter and surface finish. These machines are equipped with precision dies that can accurately reduce the diameter of the wire to the desired size. This results in a uniform wire that is free from defects and imperfections, making it suitable for a wide range of applications.

Another advantage of using aluminum wire breakdown drawing machines is the ability to increase production efficiency. These machines are capable of drawing wire at high speeds, allowing manufacturers to produce large quantities of wire in a short amount of time. This can help reduce production costs and improve overall productivity.

In addition to producing high-quality wire at high speeds, aluminum wire breakdown drawing machines are also versatile tools that can be used to produce wire of different sizes and shapes. By simply changing the dies, manufacturers can easily adjust the diameter of the wire to meet specific requirements. This flexibility makes these machines ideal for producing a wide range of wire products, from thin electrical wires to thick cables.

Furthermore, aluminum wire breakdown drawing machines are durable and reliable, making them a cost-effective investment for wire manufacturers. These machines are built to withstand the rigors of continuous operation and are designed to require minimal maintenance. This means that manufacturers can rely on these machines to produce high-quality wire consistently without the need for frequent repairs or replacements.

Additionally, aluminum wire breakdown drawing machines are energy-efficient, helping manufacturers reduce their overall energy consumption and operating costs. These machines are designed to minimize energy wastage during the Wire Drawing Process, making them an environmentally friendly option for wire manufacturers.

Overall, aluminum wire breakdown drawing machines offer a range of advantages that make them an essential tool for wire manufacturers. From producing high-quality wire with consistent diameter and surface finish to increasing production efficiency and versatility, these machines are a valuable asset for any wire manufacturing operation. With their durability, reliability, and energy efficiency, aluminum wire breakdown drawing machines are a cost-effective investment that can help manufacturers meet their production goals and deliver high-quality wire products to their customers.