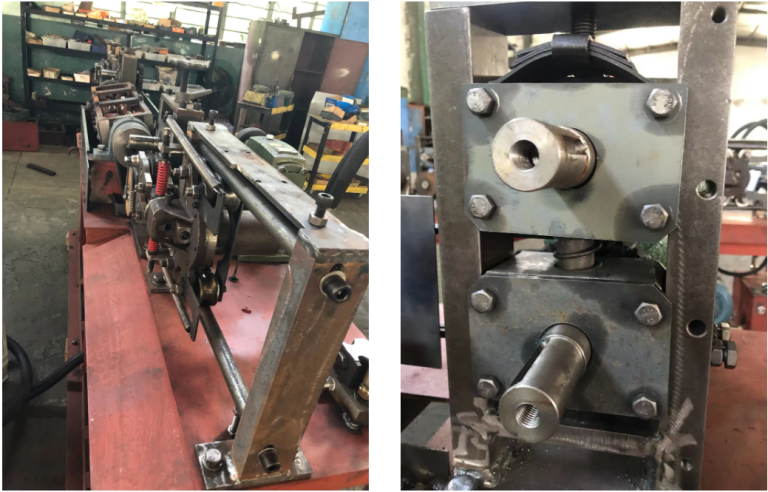

an Automatic Wire Straightening and cutting machine

Automatic wire straightening and cutting machines have revolutionized the wire processing industry by offering a fast, efficient, and precise way to straighten and cut wire. These machines are designed to handle a wide range of wire diameters and materials, making them a versatile tool for various industries such as construction, manufacturing, and automotive. In this article, we will explore the benefits of using an automatic wire straightening and cutting machine.

One of the main advantages of using an automatic wire straightening and cutting machine is the time-saving aspect. These machines are capable of straightening and cutting wire at a much faster rate than manual methods, which can significantly increase productivity and efficiency in a production environment. With the ability to process hundreds of meters of wire per minute, automatic wire straightening and cutting machines can help businesses meet tight deadlines and fulfill large orders with ease.

In addition to saving time, wire straightening and cutting machines also offer a high level of precision and accuracy. These machines are equipped with advanced technology that ensures each wire is straightened and cut to the exact length and dimensions required. This level of precision is crucial in industries where consistency and quality are paramount, such as in the manufacturing of electronic components or automotive parts.

Another benefit of using an wire straightening and cutting machine is the reduction in material waste. Manual methods of straightening and cutting wire often result in uneven cuts and wasted material, which can be costly for businesses in the long run. Automatic machines, on the other hand, are programmed to minimize waste by cutting wire to precise lengths, thereby maximizing the use of materials and reducing overall production costs.

Furthermore, wire straightening and cutting machines are designed to be user-friendly and easy to operate. These machines are equipped with intuitive controls and settings that allow operators to quickly set up and adjust the machine for different wire sizes and specifications. This ease of use not only saves time but also reduces the risk of errors and accidents, making automatic wire straightening and cutting machines a safe and reliable option for businesses of all sizes.

In conclusion, the benefits of using an automatic wire straightening and cutting machine are numerous and can have a significant impact on a business’s productivity, efficiency, and bottom line. From saving time and reducing material waste to ensuring precision and accuracy, these machines offer a cost-effective solution for wire processing needs. Whether you are in the construction, manufacturing, or automotive industry, investing in an automatic wire straightening and cutting machine can help streamline your operations and improve overall performance.