How to Choose the Right Belt Descaler for Steel Wire Rod

When it comes to the production of steel wire rod, one of the key processes involved is Sand Belt Grinding Descaler. Descaling is the removal of mill scale, rust, and other impurities from the surface of the steel wire rod to ensure a clean and smooth finish. One of the most effective tools for descaling steel wire rod is a belt descaler.

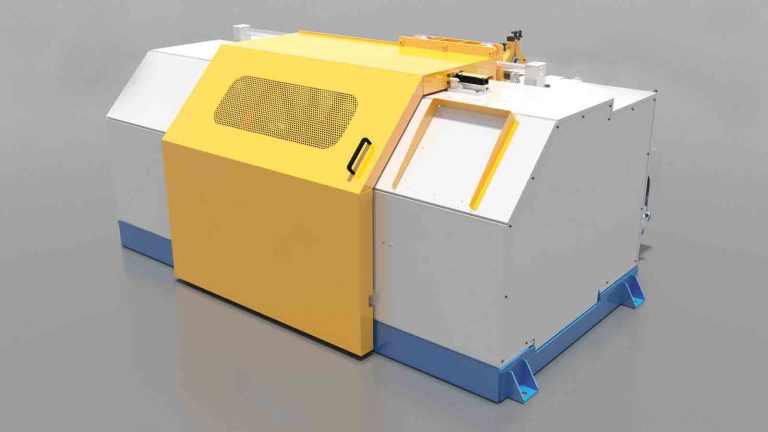

A belt descaler is a machine that uses abrasive belts to remove scale and other impurities from the surface of the steel wire rod. There are several factors to consider when choosing the right belt descaler for your steel wire rod production line.

First and foremost, you need to consider the size and capacity of the belt descaler. The size of the belt descaler should be compatible with the size of your steel wire rod production line. It should be able to handle the volume of steel wire rod that you need to descale on a daily basis. Additionally, the capacity of the belt descaler should be sufficient to meet your production needs without causing any bottlenecks in the production process.

Another important factor to consider when choosing a belt sinding grinder for steel wire rod is the type of abrasive belts used in the machine. Different abrasive belts are designed for different types of descaling applications. For steel wire rod descaling, it is important to choose abrasive belts that are specifically designed for this purpose. These belts should be able to effectively remove scale and other impurities from the surface of the steel wire rod without causing any damage to the material.

In addition to the size, capacity, and type of abrasive belts, you should also consider the speed and efficiency of the belt descaler. The speed at which the belt descaler operates will directly impact the productivity of your steel wire rod production line. A faster belt descaler will be able to descale more steel wire rod in a shorter amount of time, increasing overall production efficiency.

Furthermore, the efficiency of the belt descaler is crucial in ensuring that the descaling process is thorough and effective. A high-efficiency belt descaler will be able to remove scale and other impurities from the surface of the steel wire rod with minimal waste and rework. This will result in a cleaner and smoother finish on the steel wire rod, improving the quality of the final product.

When choosing a belt descaler for steel wire rod, it is also important to consider the maintenance and upkeep of the machine. A well-maintained belt descaler will last longer and perform better, reducing downtime and maintenance costs in the long run. Make sure to choose a belt descaler that is easy to maintain and repair, with readily available spare parts and technical support.

In conclusion, choosing the right belt descaler for steel wire rod is crucial in ensuring a clean and smooth finish on the final product. Consider factors such as size, capacity, type of abrasive belts, speed, efficiency, and maintenance when selecting a belt descaler for your steel wire rod production line. By choosing the right belt descaler, you can improve the quality and efficiency of your steel wire rod production process.

Maintenance Tips for Belt Descaler in Steel Wire Rod Production

Steel wire rod production is a complex process that requires careful maintenance of equipment to ensure optimal performance. One crucial piece of equipment in this process is the belt descaler, which plays a key role in removing scale and impurities from the steel wire rod. Proper maintenance of the belt descaler is essential to ensure that it operates efficiently and effectively.

One important maintenance tip for the sand belt grinder is to regularly inspect and clean the belts. Over time, scale and debris can build up on the belts, reducing their effectiveness in removing impurities from the steel wire rod. By regularly inspecting and cleaning the belts, you can ensure that they are functioning properly and are able to effectively remove scale and impurities from the wire rod.

In addition to cleaning the belts, it is also important to regularly check the alignment of the belts. Misaligned belts can cause uneven wear and reduce the effectiveness of the descaling process. By regularly checking the alignment of the belts and making any necessary adjustments, you can ensure that the belt descaler is operating at peak performance.

Another important maintenance tip for the belt descaler is to regularly inspect and replace the brushes. The brushes play a crucial role in removing scale and impurities from the wire rod, and over time, they can become worn and less effective. By regularly inspecting the brushes and replacing them when necessary, you can ensure that the belt descaler is able to effectively remove scale and impurities from the wire rod.

It is also important to regularly check the water supply to the belt descaler. The water is used to help remove scale and impurities from the wire rod, and if the water supply is not sufficient, the descaling process may be less effective. By regularly checking the water supply and ensuring that it is at the proper level, you can ensure that the belt descaler is able to effectively remove scale and impurities from the wire rod.

In addition to these maintenance tips, it is also important to regularly inspect the overall condition of the belt descaler. Look for any signs of wear or damage, such as cracks or corrosion, and address any issues promptly to prevent further damage and ensure that the belt descaler continues to operate effectively.

By following these maintenance tips, you can ensure that your belt descaler is able to effectively remove scale and impurities from the steel wire rod, helping to improve the quality of the finished product. Proper maintenance of the belt descaler is essential to ensure that it operates efficiently and effectively, so be sure to regularly inspect and clean the belts, check the alignment, inspect and replace the brushes, monitor the water supply, and inspect the overall condition of the equipment. By taking these steps, you can help to ensure that your steel wire rod production process runs smoothly and efficiently.