Merits of Using Belt Descaler For Steel Wire Rod Surface Pre-Treatment

Steel wire rods are a crucial component in various industries, including construction, automotive, and manufacturing. These rods are used to create a wide range of products, from nails and screws to cables and springs. To ensure the quality and durability of these products, it is essential to properly treat the surface of the steel wire rods before further processing.

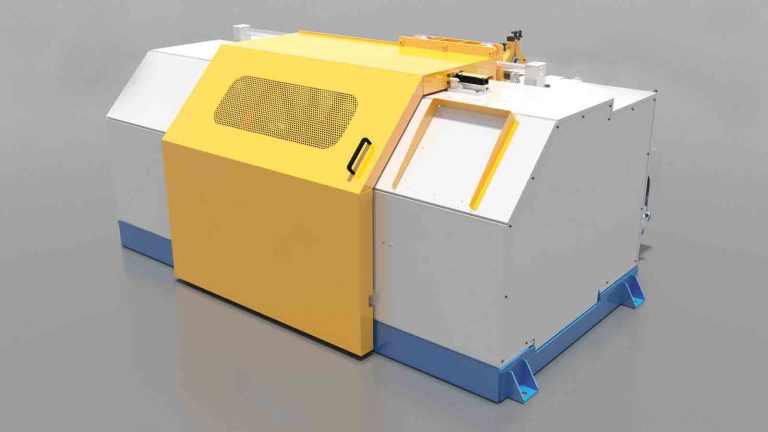

One effective method for surface pre-treatment of steel wire rods is using a belt descaler. A belt descaler is a machine that removes scale, rust, and other impurities from the surface of the steel wire rods, leaving them clean and ready for further processing. There are several benefits to using a belt descaler for steel wire rod surface pre-treatment.

First and foremost, using a belt descaler ensures that the surface of the steel wire rods is free from any contaminants that could affect the quality of the final product. Scale, rust, and other impurities can weaken the steel wire rods and make them more prone to corrosion. By removing these impurities with a belt descaler, manufacturers can produce high-quality steel wire rods that meet industry standards and customer expectations.

Additionally, using a belt descaler for steel wire rod surface pre-treatment can improve the efficiency of the manufacturing process. When the surface of the steel wire rods is clean and free from impurities, it is easier to process them further, whether that involves drawing, annealing, or coating. This can lead to higher productivity and lower production costs, as the steel wire rods will require less time and energy to process.

Another benefit of using a belt descaler for steel wire rod surface pre-treatment is that it can extend the lifespan of the equipment used in the manufacturing process. Scale, rust, and other impurities can cause wear and tear on machinery, leading to costly repairs and downtime. By keeping the surface of the steel wire rods clean with a belt descaler, manufacturers can reduce the risk of equipment failure and prolong the lifespan of their machinery.

Furthermore, using a belt descaler for steel wire rod surface pre-treatment can improve the overall quality of the final products. Clean, scale-free steel wire rods are more likely to meet industry standards for strength, durability, and appearance. This can enhance the reputation of the manufacturer and increase customer satisfaction, leading to repeat business and referrals.

In conclusion, using a belt descaler for steel wire rod surface pre-treatment offers numerous benefits for manufacturers in various industries. From ensuring the quality of the final products to improving efficiency and prolonging equipment lifespan, a belt descaler is an essential tool for any manufacturer working with steel wire rods. By investing in a belt descaler, manufacturers can enhance their production processes and deliver high-quality products that meet industry standards and customer expectations.

How to Choose the Right Belt Descaler for Steel Wire Rod Surface Pre-Treatment

Steel wire rods are an essential component in various industries, including construction, automotive, and manufacturing. Before these wire rods can be used in the production process, they must undergo surface pre-treatment to remove any impurities and contaminants. One crucial step in this pre-treatment process is descaling, which involves removing scale and rust from the surface of the wire rods to ensure optimal adhesion of coatings and improve overall product quality.

One effective method for descaling steel wire rods is using a belt descaler. Belt descalers are machines designed to remove scale and rust from the surface of wire rods by passing them through a series of abrasive belts. These belts are typically made of abrasive materials such as silicon carbide or aluminum oxide, which are effective at removing scale and rust without damaging the surface of the wire rods.

When choosing a belt descaler for steel wire rod surface pre-treatment, there are several factors to consider to ensure that you select the right machine for your specific needs. One of the most important factors to consider is the size and capacity of the belt descaler. The size of the machine will determine the maximum diameter and length of wire rods that can be processed, so it is essential to choose a machine that can accommodate the size of wire rods you will be descaling.

Another important factor to consider when choosing a belt descaler is the speed and efficiency of the machine. The speed at which the wire rods can be processed will impact the overall productivity of your operation, so it is crucial to choose a machine that can descale wire rods quickly and efficiently. Additionally, the quality of the abrasive belts used in the machine will also impact the efficiency of the descaling process, so it is essential to choose a machine that uses high-quality abrasive belts that can effectively remove scale and rust from the surface of the wire rods.

In addition to size, capacity, speed, and efficiency, it is also important to consider the overall durability and reliability of the belt descaler. A reliable machine will ensure consistent and high-quality descaling results, reducing downtime and maintenance costs. It is essential to choose a machine from a reputable manufacturer with a proven track record of producing high-quality belt descalers that are built to last.

Furthermore, it is crucial to consider the safety features of the belt descaler to ensure the safety of operators and workers. Look for machines that are equipped with safety guards, emergency stop buttons, and other safety features to prevent accidents and injuries during operation.

In conclusion, choosing the right belt descaler for steel wire rod surface pre-treatment is essential to ensure the quality and efficiency of the descaling process. Consider factors such as size, capacity, speed, efficiency, durability, reliability, and safety features when selecting a belt descaler for your operation. By choosing a high-quality machine from a reputable manufacturer, you can ensure that your wire rods are descaled effectively and efficiently, leading to improved product quality and overall production efficiency.

Maintenance Tips for Belt Descaler Used in Steel Wire Rod Surface Pre-Treatment

Steel wire rod surface pre-treatment is a crucial step in the manufacturing process to ensure the quality and durability of the final product. One of the key tools used in this process is the belt descaler, which helps remove scale and impurities from the surface of the wire rod. Proper maintenance of the belt descaler is essential to ensure its optimal performance and longevity.

Regular cleaning of the belt descaler is important to prevent the build-up of scale and debris, which can affect its efficiency. It is recommended to clean the descaler after each use to remove any residue that may have accumulated during the pre-treatment process. This can be done using a brush or compressed air to dislodge any particles stuck to the belt.

In addition to regular cleaning, it is also important to inspect the belt descaler for any signs of wear or damage. Check the belt for any tears or fraying, as this can affect its ability to effectively remove scale from the wire rod surface. Replace the belt if necessary to ensure optimal performance.

Proper lubrication of the belt descaler is another important maintenance tip to keep in mind. Lubricate the moving parts of the descaler regularly to reduce friction and wear, which can prolong the life of the equipment. Use a lubricant recommended by the manufacturer to ensure compatibility with the descaler’s components.

Regular inspection of the belt descaler’s components is also essential to identify any potential issues before they escalate. Check the bearings, rollers, and other moving parts for signs of wear or damage, and replace them as needed. This will help prevent unexpected breakdowns and downtime during the pre-treatment process.

In addition to regular maintenance, it is important to follow the manufacturer’s guidelines for operating the belt descaler. This includes using the correct settings and parameters for the pre-treatment process to ensure optimal performance. Avoid overloading the descaler or running it at excessive speeds, as this can cause unnecessary wear and damage to the equipment.

Proper training of personnel operating the belt descaler is also crucial to ensure its safe and effective use. Make sure that operators are familiar with the equipment’s operation and maintenance procedures to prevent accidents and ensure consistent results in the pre-treatment process.

Overall, proper maintenance of the belt descaler is essential to ensure its optimal performance and longevity in steel wire rod surface pre-treatment. By following these maintenance tips and guidelines, you can help prolong the life of the equipment and achieve high-quality results in the manufacturing process. Remember to clean, inspect, lubricate, and operate the descaler according to the manufacturer’s recommendations to keep it running smoothly and efficiently.