How to Choose the Right Water Tank wire drawing machine for Staple Nail Wire

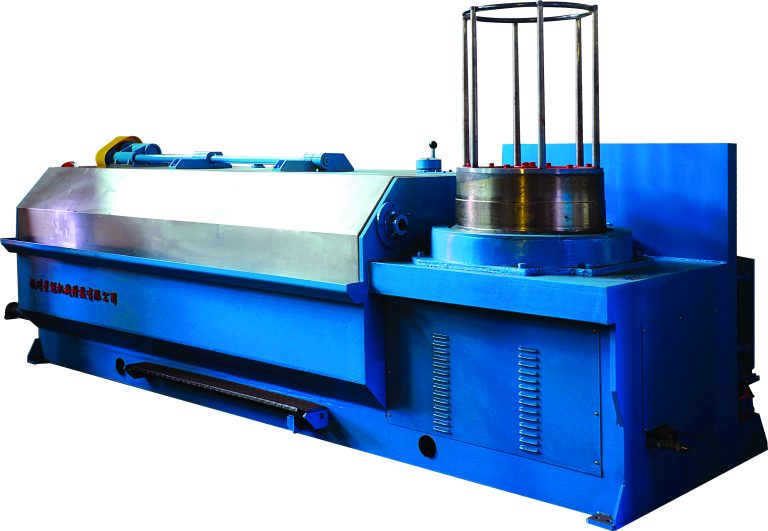

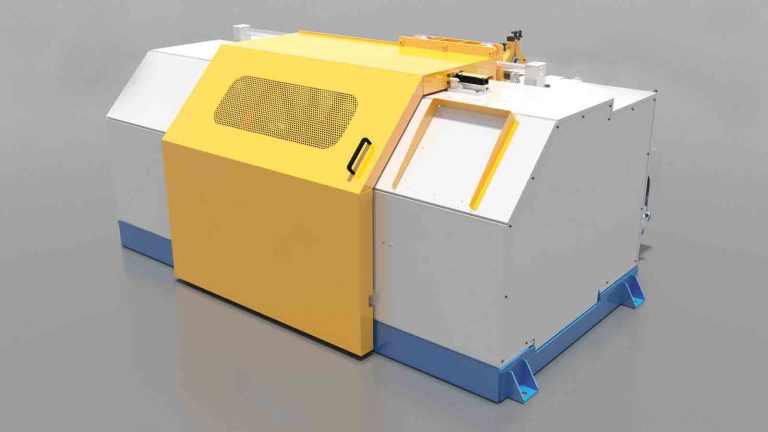

When it comes to manufacturing staple nail wire, having the right equipment is crucial to ensure a smooth and efficient production process. One key piece of machinery that is essential for this purpose is the water tank wire drawing machine. This machine plays a vital role in the Wire Drawing Process, which is necessary to produce high-quality staple nail wire.

There are several factors to consider when choosing the right water tank wire drawing machine for staple nail wire production. One of the most important factors to consider is the size and capacity of the machine. The size of the machine should be able to accommodate the volume of wire that needs to be drawn. It is important to choose a machine that is large enough to handle the production requirements without being too bulky or cumbersome.

Another important factor to consider is the speed and efficiency of the machine. The wire drawing process can be time-consuming, so it is important to choose a machine that can operate at a high speed without compromising the quality of the wire. Look for a machine that offers variable speed settings to allow for flexibility in production.

In addition to size and speed, it is also important to consider the quality and durability of the machine. Look for a machine that is made from high-quality materials and is built to last. A durable machine will be able to withstand the rigors of daily use and provide consistent performance over time.

When choosing a water tank wire drawing machine, it is also important to consider the power source. Some machines are powered by electricity, while others may be powered by hydraulic systems. Consider the power requirements of your production facility and choose a machine that is compatible with your existing power source.

It is also important to consider the maintenance requirements of the machine. Look for a machine that is easy to clean and maintain, as regular maintenance is essential to ensure optimal performance. Choose a machine that comes with a warranty or service agreement to provide peace of mind in case of any issues.

When selecting a water tank wire drawing machine, it is important to consider the reputation of the manufacturer. Look for a reputable manufacturer with a track record of producing high-quality machinery. Read reviews and testimonials from other customers to get an idea of the quality and reliability of the machine.

In conclusion, choosing the right water tank wire drawing machine for staple nail wire production is essential to ensure a smooth and efficient manufacturing process. Consider factors such as size, speed, quality, power source, maintenance requirements, and manufacturer reputation when making your decision. By taking the time to research and evaluate your options, you can find a machine that meets your production needs and helps you produce high-quality staple nail wire.

Benefits of Using Water Tank Wire Drawing Machine for Staple Nail Wire

Wire drawing is a process used to reduce the diameter of a wire by pulling it through a series of dies. This process is commonly used in the manufacturing of staple nail wire, which is a crucial component in the construction industry. To achieve the desired diameter and quality of staple nail wire, manufacturers often rely on water tank wire drawing machines.

One of the key benefits of using a water tank wire drawing machine for Staple Wire Wet Drawing Machine is the improved quality of the final product. The water tank serves as a cooling mechanism during the drawing process, which helps to prevent overheating and maintain the integrity of the wire. This results in a smoother surface finish and more consistent diameter throughout the length of the wire, which is essential for producing high-quality staple nails.

In addition to improving the quality of the wire, water tank wire drawing machines also offer increased efficiency in the manufacturing process. The cooling effect of the water tank allows for higher drawing speeds, which means that more wire can be produced in a shorter amount of time. This not only increases productivity but also reduces production costs, making the manufacturing process more cost-effective overall.

Furthermore, water tank wire drawing machines are known for their durability and reliability. The water tank helps to dissipate heat generated during the drawing process, which reduces wear and tear on the dies and other components of the machine. This results in less frequent maintenance and downtime, allowing manufacturers to operate their wire drawing machines more consistently and efficiently.

Another advantage of using a water tank wire drawing machine for staple nail wire is the flexibility it offers in terms of wire diameter and material. These machines can accommodate a wide range of wire sizes and materials, allowing manufacturers to produce staple nail wire to meet specific requirements and standards. Whether it’s stainless steel, carbon steel, or another material, a water tank wire drawing machine can handle the job with precision and accuracy.

Additionally, water tank wire drawing machines are designed with safety in mind. The cooling effect of the water tank helps to reduce the risk of overheating and potential hazards associated with high-speed wire drawing. This ensures a safer working environment for operators and minimizes the risk of accidents or injuries during the manufacturing process.

In conclusion, the benefits of using a water tank wire drawing machine for staple nail wire are clear. From improved quality and efficiency to durability, flexibility, and safety, these machines offer a range of advantages that make them an essential tool for manufacturers in the construction industry. By investing in a water tank wire drawing machine, manufacturers can enhance their production processes, increase productivity, and ultimately deliver high-quality staple nail wire to meet the demands of their customers.

Maintenance Tips for Water Tank Wire Drawing Machine for Staple Nail Wire

Water tank wire drawing machines are essential equipment in the production of staple nail wire. These machines play a crucial role in the wire drawing process, where metal wire is pulled through a series of dies to reduce its diameter and improve its quality. To ensure the smooth operation and longevity of your water tank wire drawing machine, proper maintenance is key.

One of the most important maintenance tasks for a water tank wire drawing machine is regular cleaning. Over time, dirt, dust, and debris can accumulate on the machine’s components, leading to decreased efficiency and potential damage. It is recommended to clean the machine after each use to prevent buildup and ensure optimal performance.

When cleaning the machine, be sure to use a soft brush or cloth to gently remove any dirt or debris. Avoid using harsh chemicals or abrasive materials, as these can damage the machine’s delicate components. Pay special attention to the wire drawing dies, as any buildup on these surfaces can affect the quality of the wire produced.

In addition to regular cleaning, it is important to lubricate the machine’s moving parts to prevent friction and wear. Lubrication should be done according to the manufacturer’s recommendations, using a high-quality lubricant suitable for the machine’s specific components. Be sure to check the oil levels regularly and top up as needed to keep the machine running smoothly.

Another important maintenance task for a water tank wire drawing machine is inspecting and replacing worn or damaged parts. Over time, the machine’s components can wear out or become damaged, leading to decreased performance and potential breakdowns. Regularly inspecting the machine for signs of wear and tear, such as cracks, dents, or corrosion, can help prevent costly repairs and downtime.

If any parts are found to be worn or damaged, it is important to replace them promptly to avoid further damage to the machine. Be sure to use genuine replacement parts from the manufacturer to ensure compatibility and optimal performance. Keep a record of all maintenance and repairs performed on the machine to track its condition and identify any recurring issues.

In addition to regular maintenance tasks, it is important to follow proper operating procedures when using a water tank wire drawing machine. Avoid overloading the machine or running it at excessive speeds, as this can cause unnecessary strain and damage. Always follow the manufacturer’s guidelines for operating the machine safely and efficiently.

By following these maintenance tips, you can ensure the smooth operation and longevity of your water tank wire drawing machine for staple nail wire. Regular cleaning, lubrication, inspection, and replacement of worn parts are essential to keep the machine running at its best. By taking care of your machine, you can maximize its performance and productivity, ultimately leading to a more efficient and profitable wire drawing process.