The Importance Of Static coiler with horizontal capstan in dustry

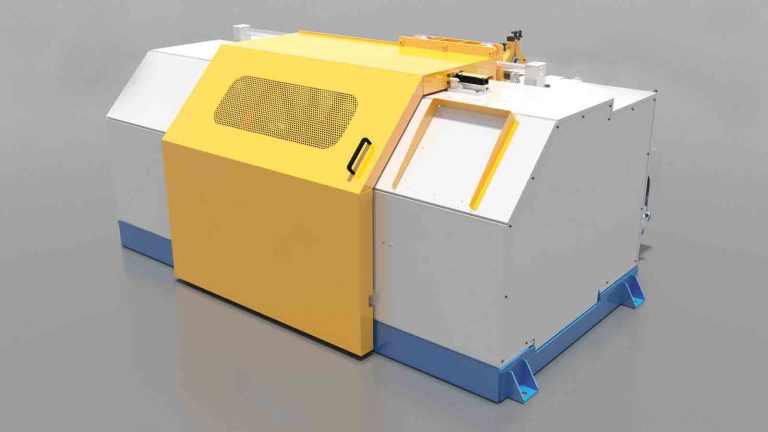

A static Dead Block Coiler with a horizontal capstan is a valuable piece of equipment that offers numerous benefits in various industries. This innovative technology is designed to efficiently coil materials such as wire, cable, rope, and tubing. By utilizing a horizontal capstan, the static coiler ensures a smooth and controlled winding process, resulting in neatly coiled products that are ready for storage or transportation.

One of the key benefits of using a static coiler with a horizontal capstan is its ability to increase productivity. The horizontal capstan allows for continuous and uniform winding of materials, reducing the time and effort required to coil them manually. This not only speeds up the production process but also ensures consistent and high-quality coils every time.

In addition to improving productivity, a Wire Dead Block Coiler Machine with a horizontal capstan also helps to minimize material waste. By precisely controlling the tension and speed of the winding process, this equipment can prevent overstretching or tangling of materials, which can lead to costly waste. This results in higher efficiency and cost savings for businesses that rely on coiled materials in their operations.

Furthermore, the use of a static coiler with a horizontal capstan can enhance workplace safety. Manual coiling processes can be labor-intensive and pose risks of injury to workers. By automating the coiling process with a static coiler, companies can reduce the physical strain on their employees and create a safer working environment. This not only protects workers from potential injuries but also improves overall morale and productivity in the workplace.

Another advantage of using a static coiler with a horizontal capstan is its versatility. This equipment can accommodate a wide range of materials and coil sizes, making it suitable for various industries and applications. Whether coiling thin wires or thick cables, the horizontal capstan can handle different types of materials with ease, providing flexibility and convenience for businesses with diverse coiling needs.

Moreover, a static coiler with a horizontal capstan offers precision and accuracy in the coiling process. The horizontal capstan ensures that materials are wound evenly and tightly, preventing any slippage or uneven winding that can compromise the quality of the coils. This level of precision is essential for industries that require consistent and reliable coiled products, such as the electrical, telecommunications, and construction sectors.

In conclusion, the benefits of using a static coiler with a horizontal capstan are numerous and significant. From increasing productivity and minimizing waste to enhancing workplace safety and versatility, this equipment offers a range of advantages for businesses that rely on coiled materials in their operations. By investing in a static coiler with a horizontal capstan, companies can improve their efficiency, quality, and overall performance, ultimately leading to greater success and competitiveness in the market.