Maintenance Tips for LLT-17/400 Aluminum Wire Breakdown Drawing Machine

The LLT-17/400 Aluminum Wire Breakdown Drawing Machine is a crucial piece of equipment in the wire manufacturing industry. To ensure that this machine operates efficiently and effectively, regular maintenance is essential. In this article, we will discuss some key maintenance tips for the LLT-17/400 Aluminum Wire Breakdown Drawing Machine.

First and foremost, it is important to regularly inspect the machine for any signs of wear and tear. This includes checking for loose or damaged parts, as well as ensuring that all components are properly lubricated. By conducting routine inspections, you can identify any potential issues before they escalate into more serious problems.

In addition to regular inspections, it is also important to clean the machine on a regular basis. Dust, dirt, and debris can accumulate on the machine over time, which can hinder its performance. By cleaning the machine regularly, you can prevent build-up and ensure that it continues to operate smoothly.

Another important maintenance tip for the Aluminum Alloy Wire Machine is to calibrate the machine regularly. Calibration ensures that the machine is operating at its optimal level and can help prevent issues such as uneven wire thickness or breakages. By calibrating the machine on a regular basis, you can ensure that it continues to produce high-quality wire.

It is also important to pay attention to the machine’s electrical components. Over time, electrical connections can become loose or corroded, which can lead to malfunctions. By checking the electrical components regularly and addressing any issues promptly, you can prevent electrical problems from occurring.

Additionally, it is important to follow the manufacturer’s guidelines for maintenance and servicing. The manufacturer’s guidelines provide valuable information on how to properly care for the machine and can help extend its lifespan. By following these guidelines, you can ensure that the machine continues to operate efficiently and effectively.

Lastly, it is important to keep detailed records of the machine’s maintenance history. By keeping track of when maintenance tasks were performed and any issues that were identified, you can better track the machine’s performance over time. This information can also be valuable for identifying patterns or trends that may indicate underlying issues with the machine.

In conclusion, proper maintenance is essential for ensuring the longevity and performance of the LLT-17/400 Aluminum Wire Breakdown Drawing Machine. By conducting regular inspections, cleaning the machine, calibrating it regularly, checking the electrical components, following manufacturer’s guidelines, and keeping detailed records, you can help prevent issues and ensure that the machine continues to operate at its best. By following these maintenance tips, you can help maximize the efficiency and effectiveness of the LLT-17/400 Aluminum Wire Breakdown Drawing Machine.

Advantages of Using LLT-17/400 Aluminum Wire Breakdown Drawing Machine

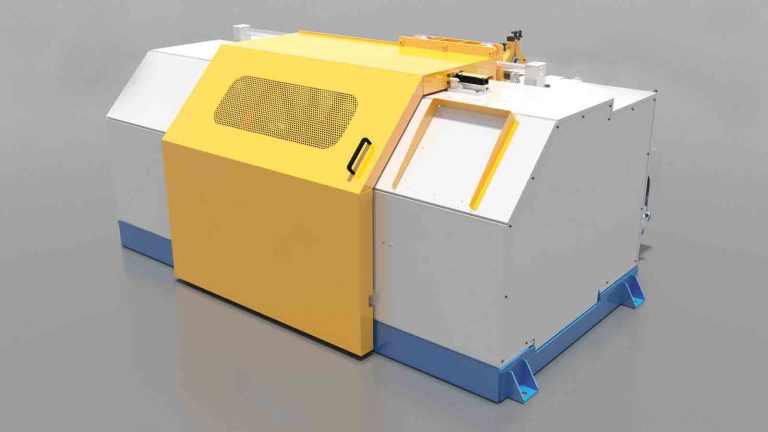

The LLT-17/400 Aluminum Wire Breakdown Drawing Machine is a cutting-edge piece of equipment that offers numerous advantages to those in the wire manufacturing industry. This machine is specifically designed to efficiently draw aluminum wire down to smaller diameters, making it an essential tool for companies looking to produce high-quality aluminum wire products.

One of the key advantages of the LLT-17/400 Aluminum Wire Breakdown Drawing Machine is its ability to consistently produce wire with precise diameters. This is crucial for ensuring that the final product meets the required specifications and standards. The machine is equipped with advanced technology that allows for accurate control of the drawing process, resulting in wire that is uniform in size and shape.

In addition to its precision, the LLT-17/400 Aluminum Wire Breakdown Drawing Machine is also known for its high production capacity. This machine is capable of drawing wire at a rapid pace, allowing manufacturers to increase their output and meet customer demands more efficiently. With this machine, companies can streamline their production process and improve overall productivity.

Another advantage of the LLT-17/400 Aluminum Wire Breakdown Drawing Machine is its versatility. This machine is designed to handle a wide range of wire diameters, making it suitable for various applications. Whether you need to draw thin wire for electronics or thicker wire for construction purposes, this machine can accommodate your needs. This versatility makes the LLT-17/400 Aluminum Wire Breakdown Drawing Machine a valuable asset for companies with diverse product lines.

Furthermore, the LLT-17/400 Aluminum Wire Breakdown Drawing Machine is known for its durability and reliability. This machine is built to withstand the rigors of continuous use in a manufacturing environment. Its robust construction and high-quality components ensure that it can operate effectively for extended periods without experiencing breakdowns or malfunctions. This reliability is essential for minimizing downtime and maximizing production efficiency.

Additionally, the LLT-17/400 Aluminum Wire Breakdown Drawing Machine is designed with user-friendly features that make it easy to operate and maintain. The machine is equipped with intuitive controls that allow operators to adjust settings and monitor the drawing process with ease. This user-friendly design helps to reduce the learning curve for new operators and ensures that the machine can be operated efficiently by personnel of varying skill levels.

Overall, the LLT-17/400 Aluminum Wire Breakdown Drawing Machine offers a range of advantages that make it a valuable investment for wire manufacturers. From its precision and high production capacity to its versatility and reliability, this machine is designed to enhance productivity and quality in the production of aluminum wire products. With its advanced technology and user-friendly features, the LLT-17/400 Aluminum Wire Breakdown Drawing Machine is a top choice for companies looking to optimize their wire drawing operations.