How To Properly Maintain And Clean A Spooling Bobbin Machines

A Spooling Bobbin Machine is a crucial piece of equipment for anyone working with thread or yarn. Whether you are a professional seamstress, a hobbyist, or a textile manufacturer, keeping your spooling bobbin machine properly maintained and clean is essential for its optimal performance and longevity.

One of the most important aspects of maintaining a Spooling Machine Horizontal is regular cleaning. Over time, dust, lint, and other debris can accumulate in the machine, causing it to jam or malfunction. To prevent this from happening, it is recommended to clean your spooling bobbin machine after every use. Start by unplugging the machine and removing any thread or yarn that may be still attached. Use a soft brush or a lint roller to gently remove any dust or lint from the machine’s exterior and interior components.

Next, inspect the bobbin case and shuttle for any signs of wear or damage. If you notice any cracks, chips, or rough edges, it is important to replace these parts immediately to prevent further damage to the machine. Additionally, check the tension settings on the machine to ensure that they are properly adjusted. Incorrect tension settings can lead to uneven winding of the thread or yarn, resulting in poor quality bobbins.

In addition to regular cleaning, it is also important to lubricate your spooling bobbin machine regularly. Lubrication helps to reduce friction between moving parts, preventing wear and tear on the machine. Before lubricating your machine, refer to the manufacturer’s instructions to determine the type of lubricant that is recommended for your specific model. Apply a small amount of lubricant to the designated areas, such as the bobbin case, shuttle, and other moving parts, to ensure smooth operation.

Another important aspect of maintaining a spooling bobbin machine is proper storage. When not in use, it is important to store your machine in a clean, dry, and dust-free environment. Avoid storing the machine near heat sources or in direct sunlight, as this can cause the plastic components to warp or become brittle. Additionally, cover your machine with a dust cover or a cloth to protect it from dust and debris.

Regular maintenance and cleaning of your spooling bobbin machine not only ensure its optimal performance but also extend its lifespan. By following these simple steps, you can keep your machine in top condition and avoid costly repairs or replacements in the future. Remember to clean your machine after every use, lubricate it regularly, and store it properly to keep it running smoothly for years to come.

In conclusion, proper maintenance and cleaning of a spooling bobbin machine are essential for its optimal performance and longevity. By following the tips outlined in this article, you can ensure that your machine operates smoothly and efficiently, allowing you to focus on your sewing projects without any interruptions. Remember to clean, lubricate, and store your machine properly to keep it in top condition for years to come.

Tips For Choosing The Right Spooling Bobbin Machine For Your Needs

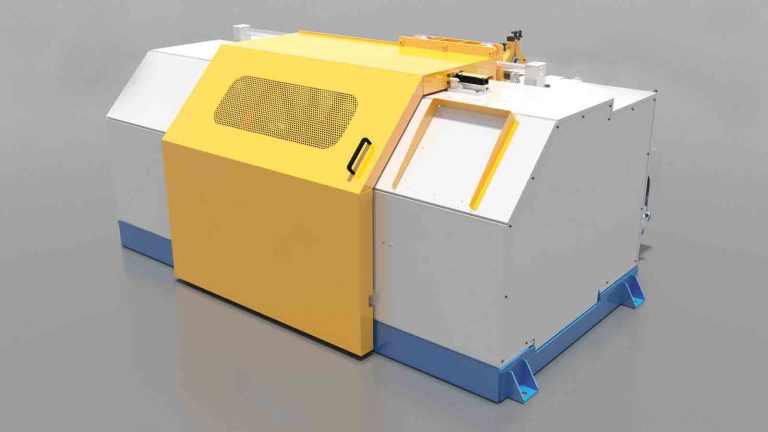

Spooling bobbin machines are essential tools for any textile or sewing business. These machines are used to wind thread onto bobbins, making it easier to feed the thread into sewing machines. Choosing the right spooling bobbin machine for your needs is crucial to ensure efficiency and productivity in your operations. There are several factors to consider when selecting a spooling bobbin machine, including the type of thread you will be using, the volume of production, and the features you require.

One of the first things to consider when choosing a spooling bobbin machine is the type of thread you will be using. Different threads have different thicknesses and textures, which can affect the winding process. Some spooling bobbin machines are designed specifically for certain types of thread, so it is important to choose a machine that is compatible with the thread you will be using. Additionally, some machines have adjustable tension settings that allow you to customize the winding process to suit the specific characteristics of the thread.

Another important factor to consider is the volume of production you will be handling. If you have a high volume of production, you will need a Automatic Spooling Machine that can keep up with the demand. Look for machines that have a high winding speed and a large capacity for bobbins. This will help you to maximize efficiency and minimize downtime.

In addition to thread type and production volume, it is also important to consider the features you require in a spooling bobbin machine. Some machines come with additional features such as automatic thread cutting, thread break detection, and programmable winding patterns. These features can help to streamline your operations and improve the quality of your finished products. However, keep in mind that machines with more features may come with a higher price tag, so it is important to weigh the benefits against the cost.

When choosing a spooling bobbin machine, it is also important to consider the reputation of the manufacturer. Look for a reputable company that has a history of producing high-quality machines. Reading reviews and testimonials from other customers can help you to gauge the reliability and performance of a particular machine. Additionally, consider the availability of spare parts and customer support services, as these can be crucial in the event of any issues or maintenance needs.

Ultimately, choosing the right spooling bobbin machine for your needs requires careful consideration of several factors. By taking into account the type of thread you will be using, the volume of production, the features you require, and the reputation of the manufacturer, you can ensure that you select a machine that meets your specific requirements. Investing in a high-quality spooling bobbin machine will help to improve the efficiency and productivity of your operations, ultimately leading to better quality products and increased customer satisfaction.