Comparison of Different Straight line wire drawing machine Models

Straight line wire drawing machines are essential tools in the manufacturing industry for producing wire of various diameters and lengths. These machines are used to pull wire through a series of dies to reduce its diameter and improve its surface finish. There are several different models of straight line wire drawing machines available on the market, each with its own unique features and capabilities. In this article, we will compare and contrast some of the most popular models to help you make an informed decision when choosing a machine for your manufacturing needs.

One of the most common types of straight line wire drawing machines is the single drum machine. This machine consists of a single drum that rotates to pull the wire through a series of dies. Single drum machines are typically used for drawing wire with larger diameters and are capable of producing high volumes of wire quickly. However, they may not be suitable for drawing wire with very small diameters or for applications that require a high degree of precision.

Another popular type of pulley type wire drawing machine is the double drum machine. This machine features two drums that rotate in opposite directions to pull the wire through the dies. Double drum machines are ideal for drawing wire with smaller diameters and for applications that require a high level of precision. They are also capable of producing wire with a smoother surface finish than single drum machines.

In addition to single and double drum machines, there are also multi-drum machines available on the market. These machines feature three or more drums that rotate to pull the wire through the dies. Multi-drum machines are ideal for drawing wire with very small diameters and for applications that require a high level of precision and surface finish. However, they are typically more expensive and complex to operate than single or double drum machines.

When choosing a straight line wire drawing machine, it is important to consider the specific requirements of your manufacturing process. If you need to produce wire with larger diameters at high volumes, a single drum machine may be the best option for you. However, if you require wire with smaller diameters and a high level of precision, a double drum or multi-drum machine may be more suitable.

It is also important to consider the speed and efficiency of the machine when making your decision. Some machines are capable of drawing wire at higher speeds than others, which can help to increase productivity and reduce production costs. Additionally, some machines may offer features such as automatic lubrication systems or digital controls that can help to improve efficiency and reduce downtime.

In conclusion, there are several different models of straight line wire drawing machines available on the market, each with its own unique features and capabilities. By carefully considering your specific requirements and the features of each machine, you can choose the best machine for your manufacturing needs. Whether you need to produce wire with larger diameters at high volumes or wire with smaller diameters and a high level of precision, there is a straight line wire drawing machine available to meet your needs.

Maintenance Tips for Straight Line Wire Drawing Machines

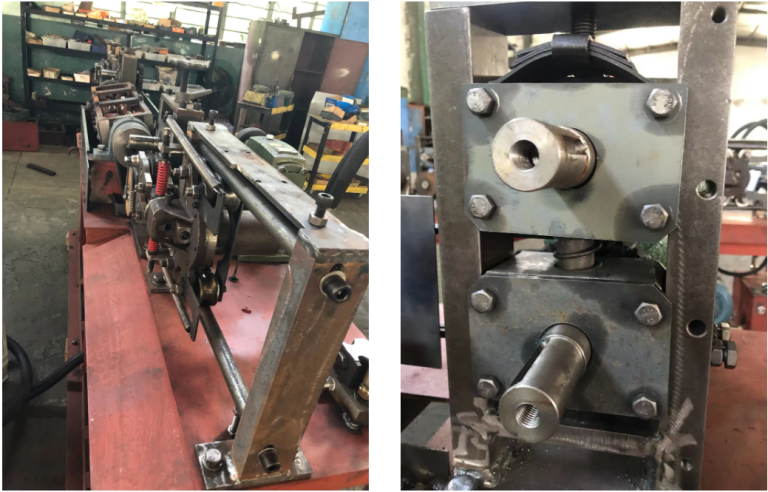

Straight line wire drawing machines are essential equipment in the manufacturing industry for producing wire of various diameters and lengths. These machines are designed to pull wire through a series of dies to reduce its diameter and improve its surface finish. To ensure the smooth operation and longevity of Straight Type Wire Drawing Machine, proper maintenance is crucial. In this article, we will discuss some maintenance tips to help you keep your straight line wire drawing machines in top condition.

Regular cleaning of the machine is essential to prevent the buildup of dirt, dust, and debris that can affect its performance. Use a soft brush or cloth to remove any particles from the machine’s surface, dies, and rollers. Pay special attention to areas where wire passes through, as any obstruction can cause wire breakage or damage to the machine.

Inspect the dies and rollers regularly for wear and tear. Replace any worn or damaged parts immediately to prevent further damage to the machine and ensure consistent wire quality. Proper lubrication of the dies and rollers is also important to reduce friction and heat generation during the Wire Drawing Process. Use a high-quality lubricant recommended by the machine manufacturer for optimal performance.

Check the tension of the wire regularly to ensure smooth drawing and prevent wire breakage. Adjust the tension settings as needed to maintain the desired wire diameter and quality. Proper tension control is crucial for achieving consistent results in wire drawing operations.

Monitor the speed of the machine to prevent overheating and excessive wear on the dies and rollers. Operating the machine at high speeds for extended periods can lead to premature failure of critical components. Adjust the speed settings according to the wire diameter and material being drawn to optimize performance and reduce maintenance costs.

Inspect the electrical components of the machine, such as motors, drives, and control systems, for any signs of wear or damage. Replace any faulty components immediately to prevent downtime and ensure the safety of operators. Regularly check the wiring and connections for loose or damaged parts that can cause electrical issues.

Perform regular calibration of the machine to ensure accurate wire diameter control and consistent drawing results. Use calibrated measuring instruments to verify the accuracy of the machine settings and make adjustments as needed. Proper calibration is essential for meeting quality standards and customer requirements.

Keep a detailed maintenance log to track the performance of the machine and schedule routine maintenance tasks. Record any issues or abnormalities observed during operation, as well as the actions taken to address them. This information will help you identify recurring problems and implement preventive measures to avoid costly repairs in the future.

In conclusion, proper maintenance of straight line wire drawing machines is essential for ensuring optimal performance and longevity. By following these maintenance tips, you can keep your machines in top condition and achieve consistent results in wire drawing operations. Remember to clean the machine regularly, inspect and replace worn parts, adjust tension and speed settings, check electrical components, calibrate the machine, and keep a detailed maintenance log. With proper care and maintenance, your straight line wire drawing machines will continue to produce high-quality wire for years to come.