-

-

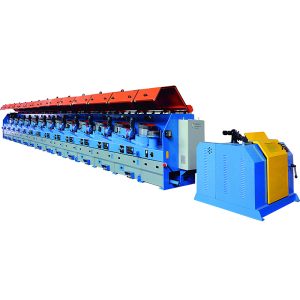

This wire drawing machine is also called Straight line drawing machine, is widely used in high carbon steel wire (SAE1060, SAE1072, SAE1072, SAW1080, SAE1082) or middle carbon steel wire production, such spring wires, MIG welding wire, CO2 welding wire(ER70S-6, SG-2), SS wire, SAW welding wire, core wire, bead wire, PC wire, bearing wire, wire rope etc.

-

It is suitable for all kinds of metal.

Cooling system : internal Drum and Die Box, both have the cooling system.

Drum : after multiple materials treatment and processing, the surface of Drum has the mirror treatment, and it can efficiently prevent wire surface scratch. It is durable, and a long life as well.

Human-Machine Interface Digital Control System & Industry 4.0 :

Electric control system provides a smooth acceleration from zero to the pre-selected value. Monitoring at office with MIS system by connecting the networks. It also could be monitored by the smart phone. Remote connection through modem allows On-line trouble shooting by Engineers.

Gear Box : gears are suitable for long time operating with high load. Long lifetime due to the surface of gears grinded based on grade 2 of JIS standard.

-

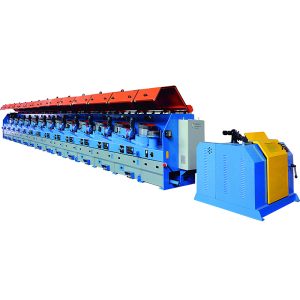

- It is suitable for all kinds of metal.

- Cooling system : internal Drum and Die Box, both have the cooling system.

- Drum : after multiple materials treatment and processing, the surface of Drum has the mirror treatment, and it can efficiently prevent wire surface scratch. It is durable, and a long life as well.

- Human-Machine Interface Digital Control System & Industry 4.0 :

- Electric control system provides a smooth acceleration from zero to the pre-selected value. Monitoring at office with MIS system by connecting the networks. It also could be monitored by the smart phone. Remote connection through modem allows On-line trouble shooting by Engineers.

- Gear Box : gears are suitable for long time operating with high load.

-

It is widely used in Zinc wire , Pure zinc wire ,Zinc Tin alloy Wire,Zinc aluminium alloy ,wire production, The final products is for Anticorrosion, food, oil pipeline industry.