Maintenance Tips for Wet Wire Drawing Machines to Ensure Optimal Performance

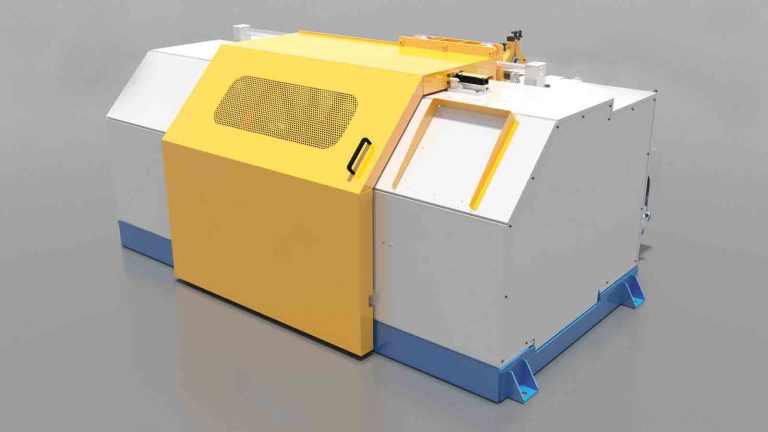

Wet wire drawing machines are essential equipment used in the manufacturing process of copper wire. These machines are designed to pull the wire through a series of dies to reduce its diameter and improve its quality. To ensure optimal performance and longevity of wet wire drawing machines, proper maintenance is crucial.

One of the most important maintenance tasks for wet wire drawing machines is regular cleaning. Over time, dirt, dust, and debris can accumulate on the machine’s components, leading to decreased efficiency and potential damage. It is recommended to clean the machine after each use to prevent buildup and ensure smooth operation.

In addition to cleaning, lubrication is another key aspect of maintenance for Copper wire drawing machines. Proper lubrication of the machine’s moving parts helps reduce friction, wear, and tear, extending the machine’s lifespan. It is important to use the correct type of lubricant and apply it according to the manufacturer’s guidelines.

Regular inspection of the machine’s components is also essential to identify any potential issues before they escalate. Check for signs of wear, corrosion, or damage on the dies, rollers, and other parts of the machine. Replace any worn or damaged components promptly to prevent further damage and ensure consistent performance.

Another important maintenance tip for wet wire drawing machines is to monitor the machine’s operating temperature. Excessive heat can cause the wire to stick to the dies, leading to quality issues and potential damage to the machine. Ensure that the machine is operating within the recommended temperature range and make adjustments as needed to maintain optimal performance.

Proper tension control is crucial for achieving the desired wire diameter and quality. Check the tension settings regularly and make adjustments as needed to ensure consistent results. Improper tension can lead to wire breakage, uneven drawing, and other issues that can affect the machine’s performance.

Regular calibration of the machine is also important to ensure accurate wire diameter and quality. Use a calibrated gauge to measure the wire diameter periodically and make adjustments to the machine’s settings as needed. This will help maintain consistent performance and quality of the wire produced.

In conclusion, proper maintenance is essential for ensuring optimal performance and longevity of wet wire drawing machines used for copper wire production. Regular cleaning, lubrication, inspection, temperature monitoring, tension control, and calibration are key maintenance tasks that should be performed regularly to keep the machine in top condition. By following these maintenance tips, manufacturers can maximize the efficiency and lifespan of their wet wire drawing machines, ultimately leading to higher quality copper wire production.

Benefits of Using Wet Wire Drawing Machines for Copper Wire Production

Staple Wire Wet Drawing Machine is an essential tool in the production of copper wire. These machines are designed to pull a wire through a series of dies to reduce its diameter and improve its quality. The process involves lubricating the wire with a coolant or lubricant to reduce friction and heat during the drawing process. This results in a smoother, more uniform wire that meets the required specifications for various applications.

One of the key benefits of using wet wire drawing machines for copper wire production is the improved quality of the wire. The lubricant used in the drawing process helps to reduce friction between the wire and the dies, resulting in a smoother surface finish. This is important for applications where the wire will be used in electrical components or other sensitive equipment. A smooth surface finish reduces the risk of damage to the wire during handling and installation, ensuring that it performs reliably in its intended application.

In addition to improving the quality of the wire, wet wire drawing machines also help to increase the production efficiency. The lubricant used in the drawing process helps to reduce heat generated during the drawing process, which can help to increase the speed at which the wire can be drawn. This means that more wire can be produced in a shorter amount of time, increasing overall productivity and reducing production costs. Additionally, the use of a lubricant can help to extend the life of the dies used in the drawing process, reducing the need for frequent replacements and maintenance.

Another benefit of using wet wire drawing machines for copper wire production is the ability to produce wire with a consistent diameter. The drawing process involves pulling the wire through a series of dies with progressively smaller diameters, resulting in a wire with a uniform diameter. This is important for applications where precise measurements are required, such as in electrical wiring or telecommunications cables. A consistent diameter ensures that the wire will fit properly in connectors and terminals, reducing the risk of connection failures or signal loss.

Furthermore, wet wire drawing machines can help to improve the overall strength and durability of the wire. The lubricant used in the drawing process helps to reduce the risk of surface defects and cracks, which can weaken the wire and reduce its lifespan. By producing wire with a smooth surface finish and consistent diameter, wet wire drawing machines can help to ensure that the wire meets the required strength and durability specifications for various applications. This is important for applications where the wire will be subjected to high levels of stress or environmental conditions, such as in automotive or aerospace applications.

In conclusion, wet wire drawing machines offer a range of benefits for copper wire production. From improving the quality and consistency of the wire to increasing production efficiency and durability, these machines play a crucial role in the manufacturing process. By using a lubricant in the drawing process, manufacturers can produce high-quality wire that meets the required specifications for a wide range of applications. Whether used in electrical wiring, telecommunications cables, or other industrial applications, wet wire drawing machines are an essential tool for producing high-quality copper wire.