Understanding the Basics of a wire drawing machine

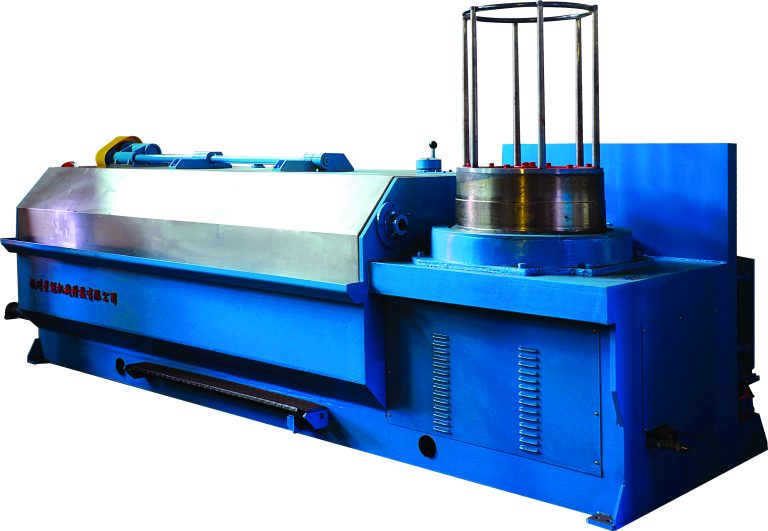

A fully automatic wire drawing machine is a piece of equipment used in the manufacturing industry to reduce the diameter of a wire by pulling it through a series of dies. This process is known as wire drawing and is essential for producing wires of various sizes and shapes for a wide range of applications. Understanding the basics of how a fully automatic wire drawing machine works can provide valuable insight into the manufacturing process and the importance of this technology.

The primary function of a wire drawing machine manufacturer is to reduce the diameter of a wire by pulling it through a series of dies. These dies are typically made of tungsten carbide or diamond and are designed to gradually decrease the diameter of the wire as it passes through them. The wire is fed into the machine from a spool and is pulled through the dies by a series of rotating capstans or pulleys. As the wire passes through each die, it is compressed and elongated, resulting in a thinner and longer wire.

One of the key components of a steel wire drawing machine is the drawing capstan, which is responsible for pulling the wire through the dies. The drawing capstan is typically made of steel or ceramic and is driven by a motor that controls the speed at which the wire is pulled through the machine. The speed of the drawing capstan can be adjusted to achieve the desired diameter and length of the wire.

In addition to the drawing capstan, a steel wire drawing machine also includes a series of dies that are used to reduce the diameter of the wire. These dies are typically made of tungsten carbide or diamond and are designed to gradually decrease the diameter of the wire as it passes through them. The number of dies used in a wire drawing machine can vary depending on the desired final diameter of the wire.

The Wire Drawing Process can be repeated multiple times to achieve the desired diameter and length of the wire. Each pass through the dies results in a thinner and longer wire, with each subsequent pass further reducing the diameter of the wire. This process is repeated until the wire reaches the desired diameter and length, at which point it is cut to size and spooled for further processing or distribution.

Straight Type Wire Drawing Machine are used in a wide range of industries, including automotive, aerospace, construction, and electronics. They are essential for producing wires of various sizes and shapes that are used in a wide range of applications, from electrical wiring to structural components. Understanding the basics of how a wire drawing machine works can provide valuable insight into the manufacturing process and the importance of this technology in modern industry.

In conclusion, a Multi Wire Drawing Machine is a piece of equipment used in the manufacturing industry to reduce the diameter of a wire by pulling it through a series of dies. This process is essential for producing wires of various sizes and shapes for a wide range of applications. By understanding the basics of how a wire drawing machine works, we can gain valuable insight into the manufacturing process and the importance of this technology in modern industry.